IiConveyors zebhanti

Intshayelelo

Eli nqaku liza kujonga nzuluiibhanti zokuhambisa.

Inqaku liza kuzisa ukuqonda ngakumbi kwimixholo efana nale:

- Ii-Conveyors zebhanti kunye nezixhobo zazo

- Iindidi zeeBhanti zokuThutha

- Uyilo kunye noKhetho lweziThuthi zeBhanti

- Usetyenziso kunye noNcedo lweziThuthi zeBhanti

- Kwaye Okuninzi…

Isahluko 1: Ii-Belt Conveyors kunye neMixholo yazo

Esi sahluko siza kuxubusha ukuba yintoni i-conveyor yebhanti kunye namalungu ayo.

Yintoni iBhanti yokuThutha?

Ukuhanjiswa kwebhanti yinkqubo eyilelwe ukuthutha okanye ukuhambisa izinto eziphathekayo njengezinto eziphathekayo, iimpahla, kunye nabantu ukusuka kwenye indawo ukuya kwenye.Ngokungafaniyo nezinye iindlela zokuhambisa ezisebenzisa amatyathanga, ii-spirals, iihydraulics, njl.Ibandakanya i-loop yezinto eziguquguqukayo ezoluliweyo phakathi kweerola eziqhutywa yimoto yombane.

Ngenxa yokuba izinto ezithuthwayo ziyahluka ngokwendalo, izinto zebhanti zikwahluka ngokwenkqubo eqeshwe kuyo. Ngokuqhelekileyo iza njengepolymer okanye ibhanti yerabha.

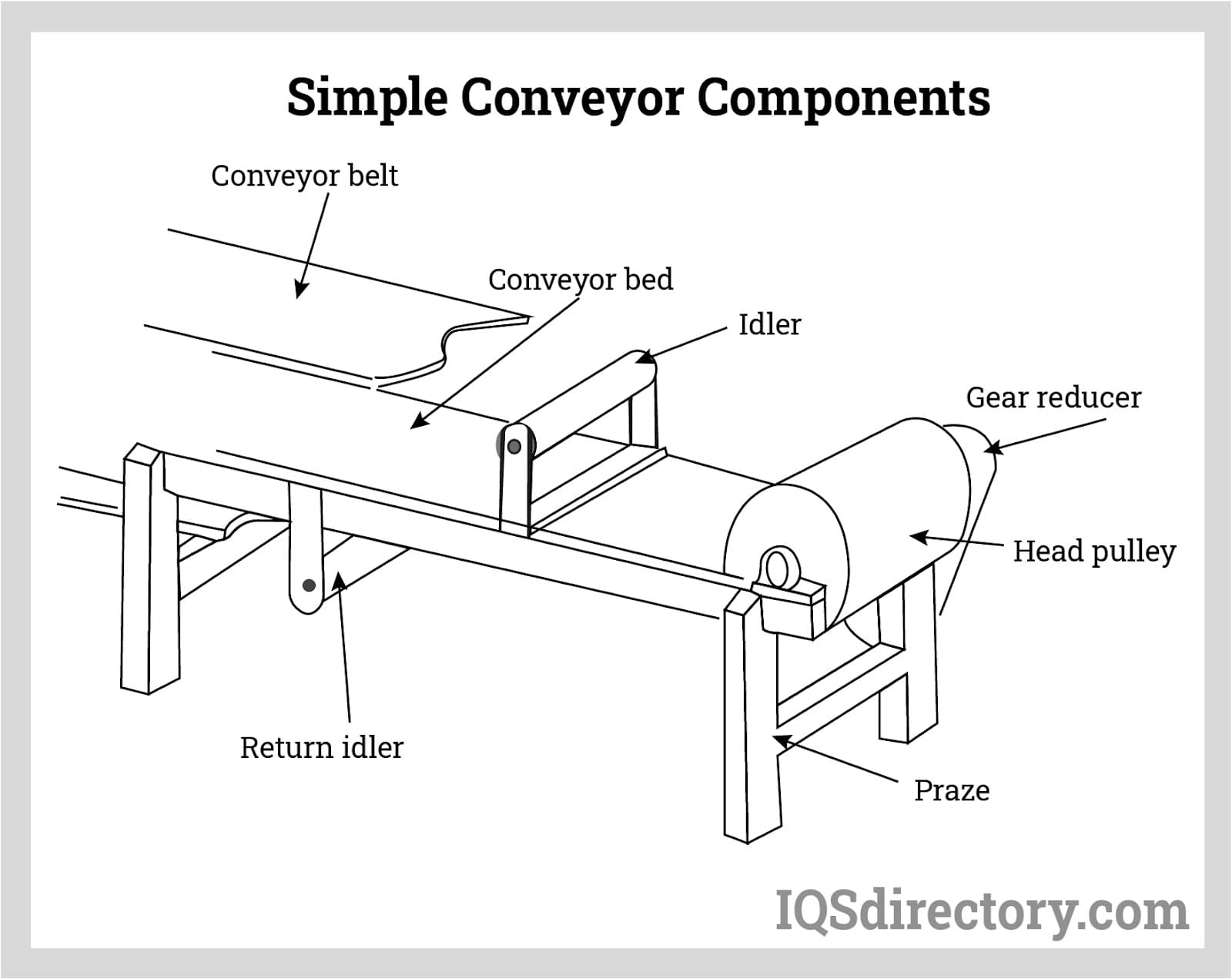

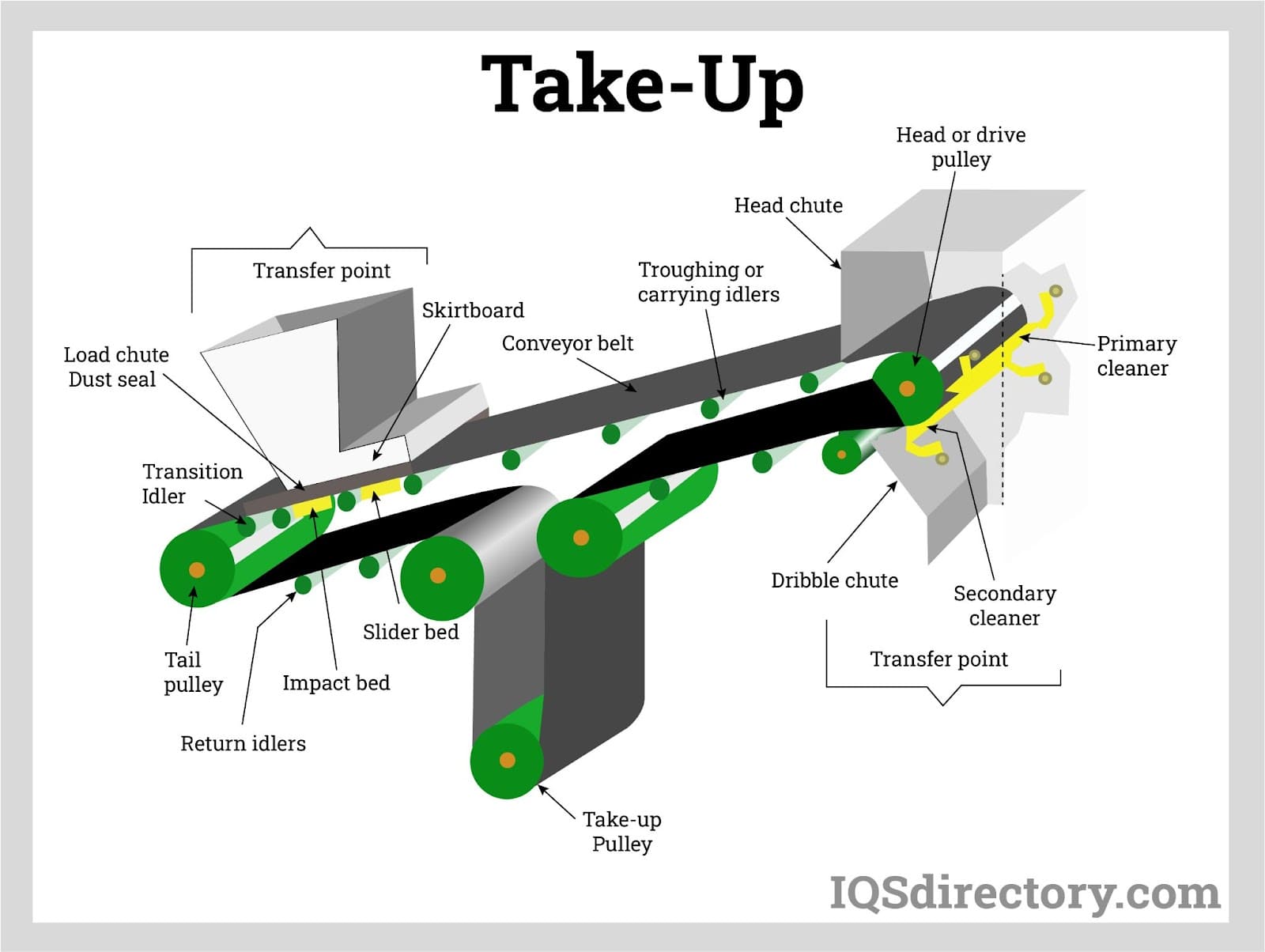

Amacandelo oMhambisi weBhanti

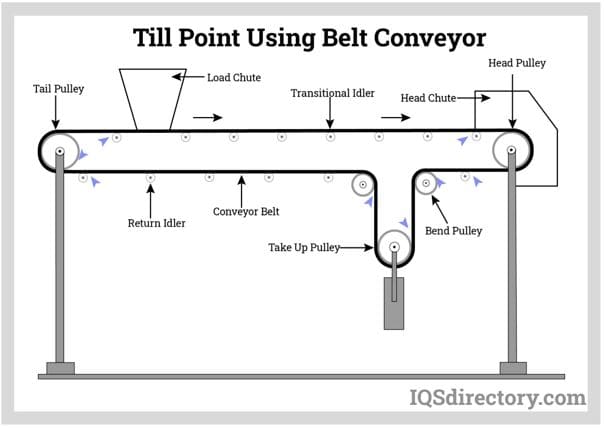

Inkqubo yokuhambisa ibhanti esemgangathweni inepuli yentloko, ipuli yomsila, iidler rollers, ibhanti kunye nefreyimu.

Intloko Pulley

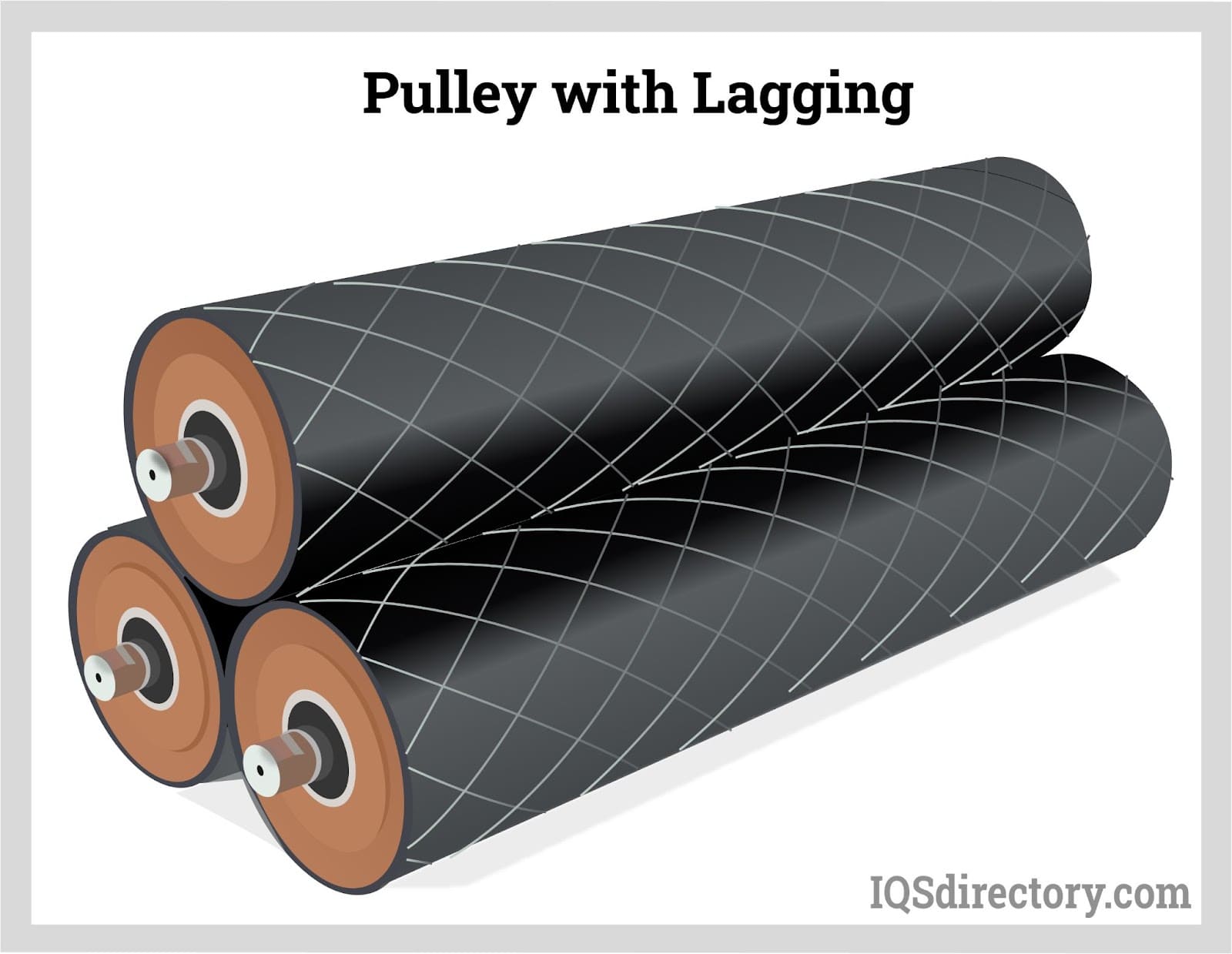

Ipuli yentloko yile idityaniswa ne actuator kunye ne motor yombane.I-pulley yentloko iqhuba umthumeli, ngokuqhelekileyo isebenza njengamandla okutsala kunokutyhala.Ikakhulu ibekwe kwindawo apho umthuthi wothulela umthwalo wayo, owaziwa ngokuba sisiphelo sokukhupha isihambisi sebhanti.Ngenxa yokuba i-pulley yentloko iqhuba yonke inkqubo, kudla ngokuyimfuneko ukunyusa i-traction yayo kunye nebhanti, ngoko kuya kuba nejacket enqabileyo egubungela indawo yayo yangaphandle.Le bhatyi ibizwa ngokuba yi-legging.Ngezantsi yintoni nayiphi na i-pulley enejacket ibonakala ngathi.

I-pulley yentloko idla ngokuba nobukhulu obukhulu kuzo zonke iipuli.Ngamanye amaxesha inkqubo ingaba neepuli ezininzi ezisebenza njengeepuli zokuqhuba.I-pulley ekupheleni kokukhupha i-driveumhambisi ongasebenziyongokuqhelekileyo inobukhulu obukhulu kwaye iya kuchongwa njenge-pulley yentloko.

Buyela okanye Umsila Pulley

Oku kukwisiphelo sokulayisha somhambisi webhanti.Ngamanye amaxesha kuza kunye nokuma kwephiko ukucoca ibhanti ngokuvumela izinto eziwela ecaleni kumalungu axhasayo.

Kulungiselelo olulula lokuhambisa ibhanti, ipulley yomsila iya kuxhonywa kwizikhokelo ezidla ngokufakwa ukuze kuvumeleke ukuxinana kwebhanti.Kwezinye iisistim zokuhambisa ibhanti njengoko siza kubona, ukuqina kwebhanti kushiyelwa kwenye irola ebizwa ngokuba yi-take-up roller.

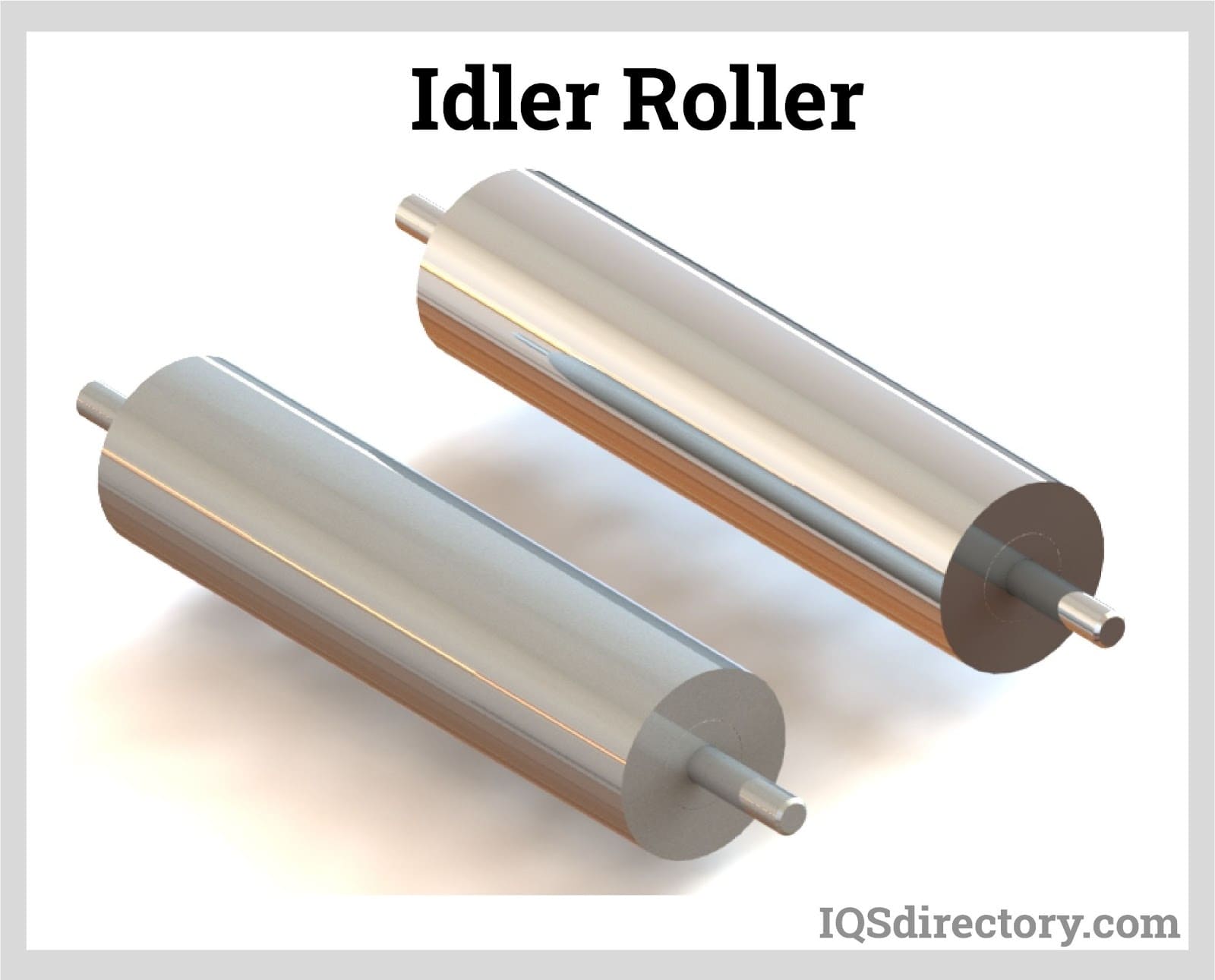

I-Idler Roller

Ezi zi-roller eziqeshwe kunye nobude bebhanti ukuxhasa ibhanti kunye nomthwalo, ukuthintela ukugoba, ukulungelelanisa ibhanti, kunye nokucoca i-carryback (izinto ezishiywe zibambelele kwibhanti).I-Idler rollers inokwenza konke oku ngasentla okanye nayiphi na enye yazo, kodwa kuyo nayiphi na indawo, baya kuhlala besebenza njengenkxaso yebhanti.

Zininzi iirola ezingasebenziyo ezahlukeneyo zemisebenzi eyahlukeneyo, njengoko zidweliswe ngezantsi:

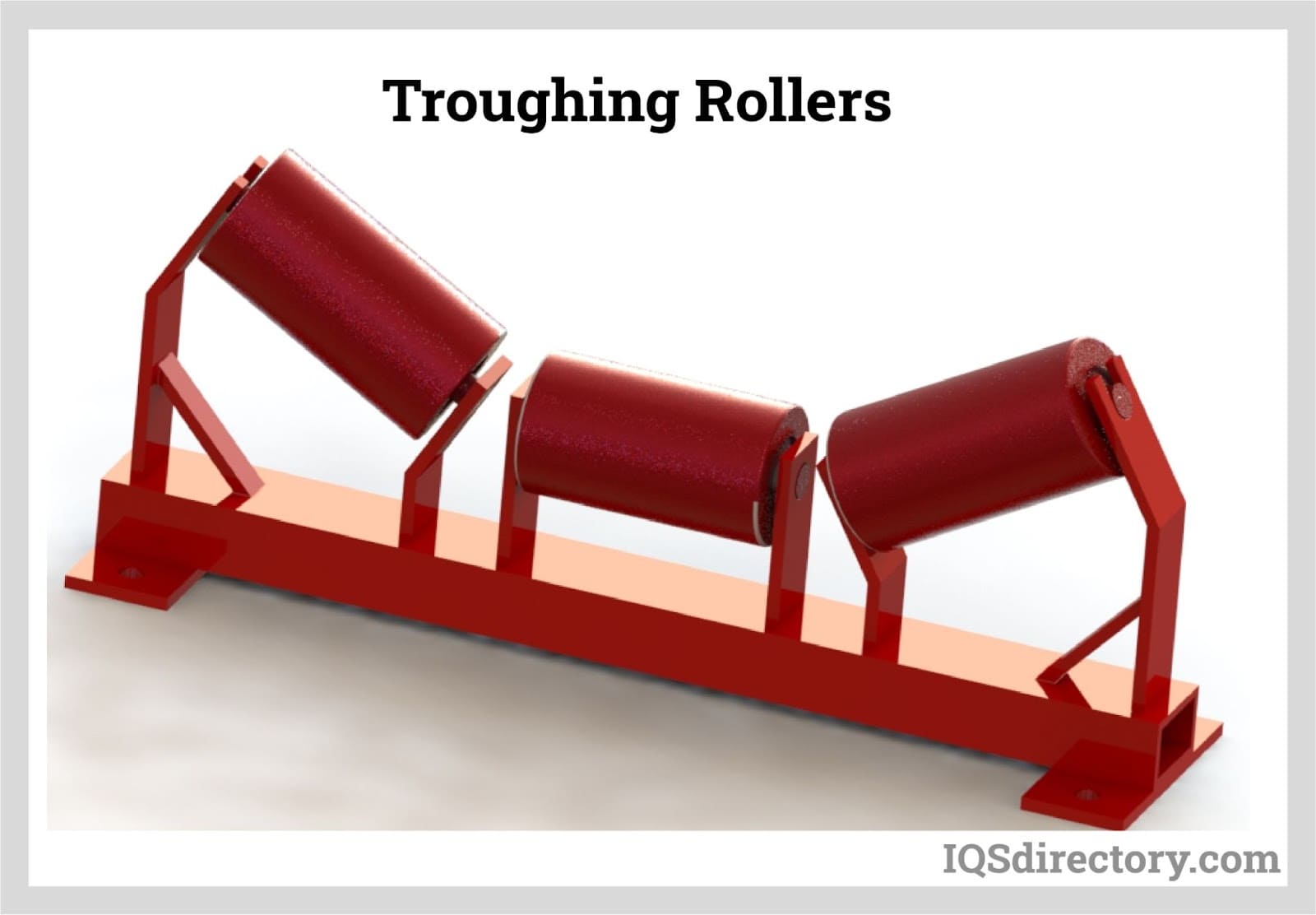

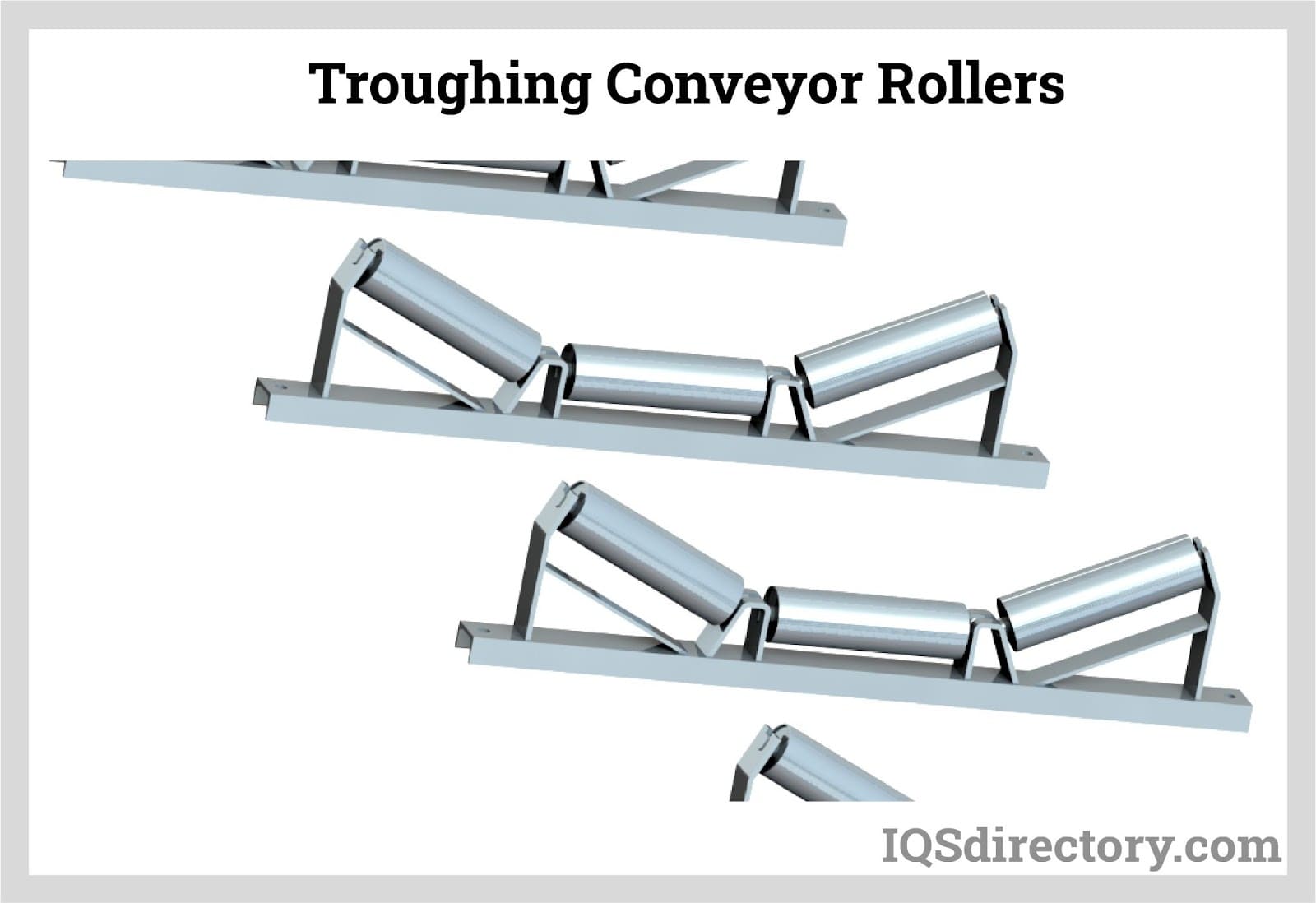

Trouughing Idlers

Amavila abhuqayo aya kuba neerola ezintathu ezingasebenziyo ezimiselwe kuqwalaselo olwenza "umkhombe" webhanti.Zibekwe kwicala elithwala umthwalo kwi-conveyor yebhanti.I-idler embindini ilungisiwe, kunye nezimbini eziphelweni ziyakwazi ukulungiswa.Oku kungoko i-engile nobunzulu bomkhombe bunokwahluka.

La mavila, xa eqeshwe, aya kunciphisa ukuchitheka kwaye agcine indawo enqamlezileyo engaguqukiyo kubude bomhambisi webhanti.Ukugcina indawo enqamlezileyo rhoqo kubalulekile ukuzinza.

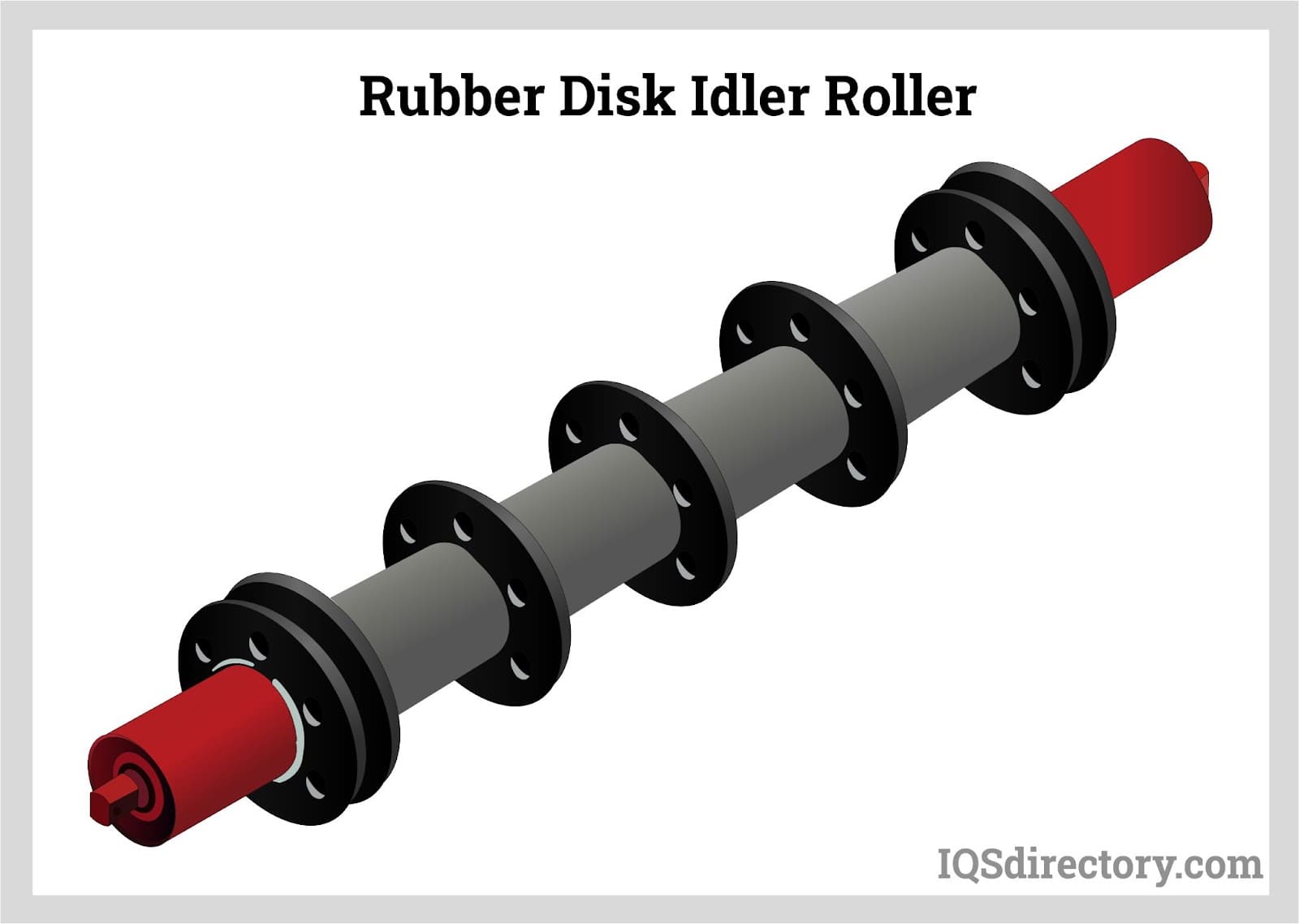

I-Rubber Disk Idler

Le idler ineediski zerabha ezibekwe kwimigama emiselweyo ecaleni kwe-axis yerola.Kwiziphelo ezigqithiseleyo, ii-roller zisondele kakhulu ukwenzela ukuba zikwazi ukuxhasa umda webhanti, ojongene nokukrazula.Iidiski ezivaliweyo ziya kuqhawula nayiphi na into edibeneyo yokuthwala / eshiyekileyo kunye nokunciphisa ukwakhiwa kwezinto phantsi kwebhanti.Esi sisizathu esiqhelekileyo sokungahambi kakuhle (xa ibhanti itshintshela kwelinye icala lenkqubo kwaye ibangele ukungahambi kakuhle).

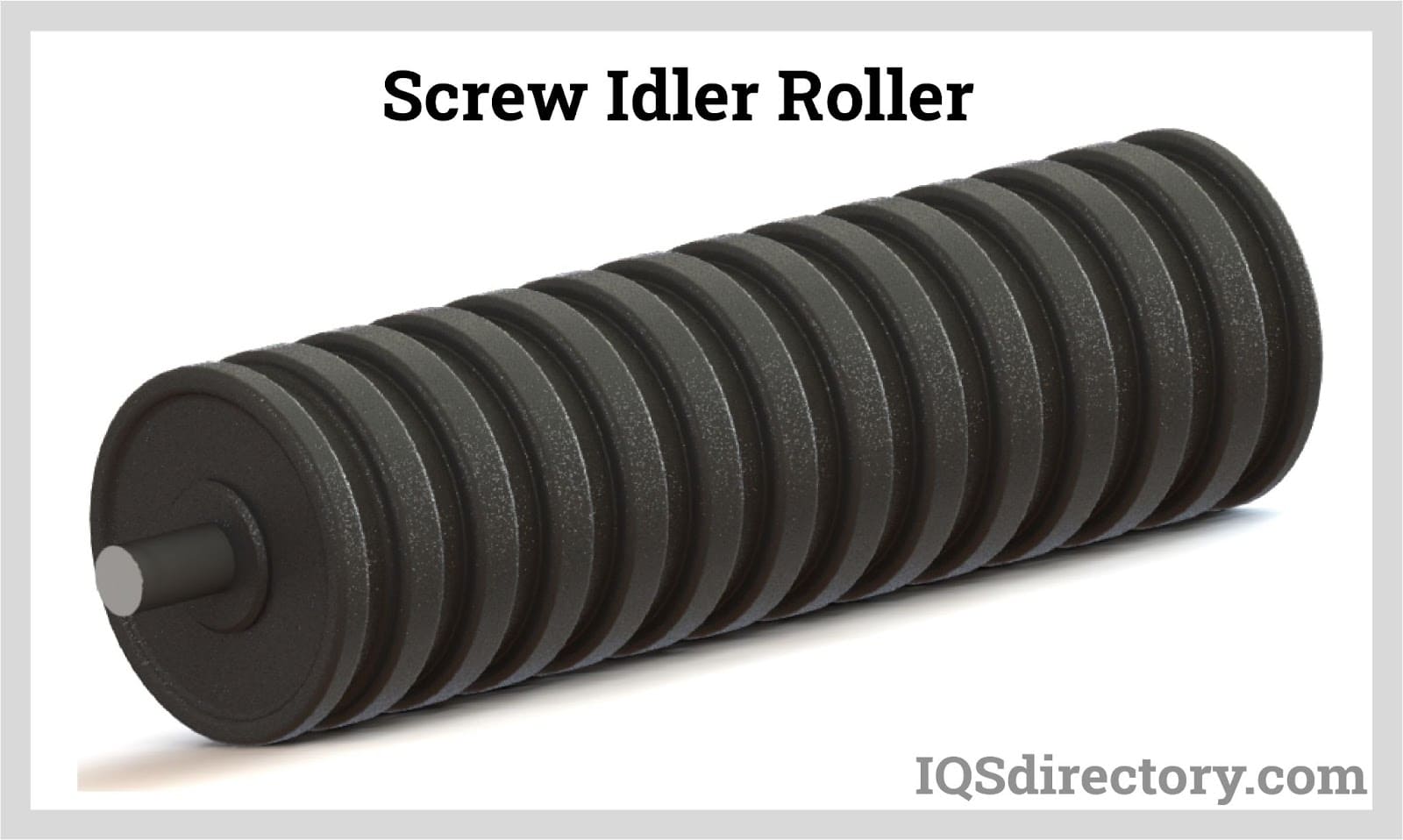

Ngamanye amaxesha iidiski ziba ne-helical njenge-screw kwaye i-idler iya kubizwa ngokuba yi-rubber screw idler roller.Umsebenzi uya kuhlala unjalo.Umzekelo we-screw idler roller ubonisiwe ngezantsi.

I-screw idler isenokwenziwa ngeheliksi yerabha.I-Screw idlers ixhaphake kakhulu apho i-scrapper ekhupha i-carryback ayinakwenzeka, ngakumbi kwii-conveyors zebhanti ezihambayo.

Umqeqeshi Idler

Abaqeqeshi abangasebenziyo bagcina ibhanti libaleka ngqo.Isebenza ngokuchasene nempazamo.Ifezekisa oku ngepivothi esembindini ethi ijike irola ibuyele embindini ukuba ibhanti likhukuliseke liye kwicala elinye.Ikwabandakanya iirola ezimbini zesikhokelo ukuba zisebenze njengezikhokelo zebhanti.

Ibhanti lokubonisa

Ekumiseni i-conveyor yebhanti, ibhanti mhlawumbi lelona lintsonkothileyo.Uxinzelelo kunye namandla abalulekile kuba ibhanti ithatha isohlwayo esikhulu xa ilayisha kwaye ihambisa izinto.

Imfuno ekhulayo yokuhambisa ixesha elide ibangele uphando kwizixhobo ezitsha, nangona oku kuhlala kusiza kwiindleko.Amabhanti anamandla abambelela ngokungqongqo kwimithetho ehambelana nokusingqongileyo athande ukuza neendleko eziphezulu zokuseta, ngamanye amaxesha iindleko azinakuthetheleleka.Ngakolunye uhlangothi, ukuba indlela yezoqoqosho ithathwa, ibhanti ngokuqhelekileyo ihluleka, okubangelwa iindleko eziphezulu zokusebenza.Iindleko zebhanti kufuneka zibe ngaphantsi kwe-50% yeendleko ezipheleleyo zokuhambisa ibhanti.

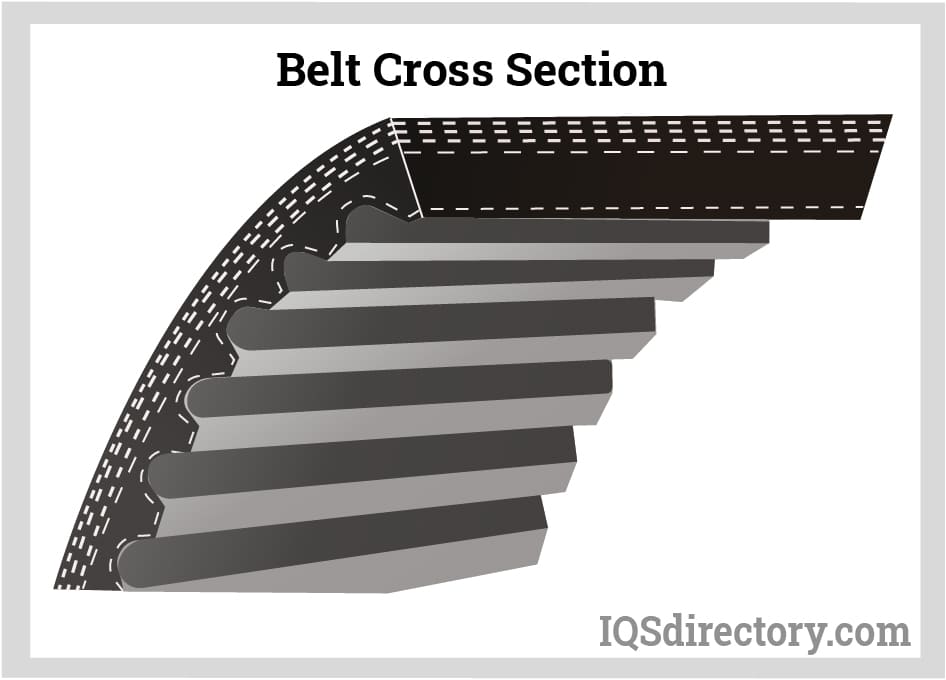

Ibhanti yenziwe ngamacandelo afana nala:

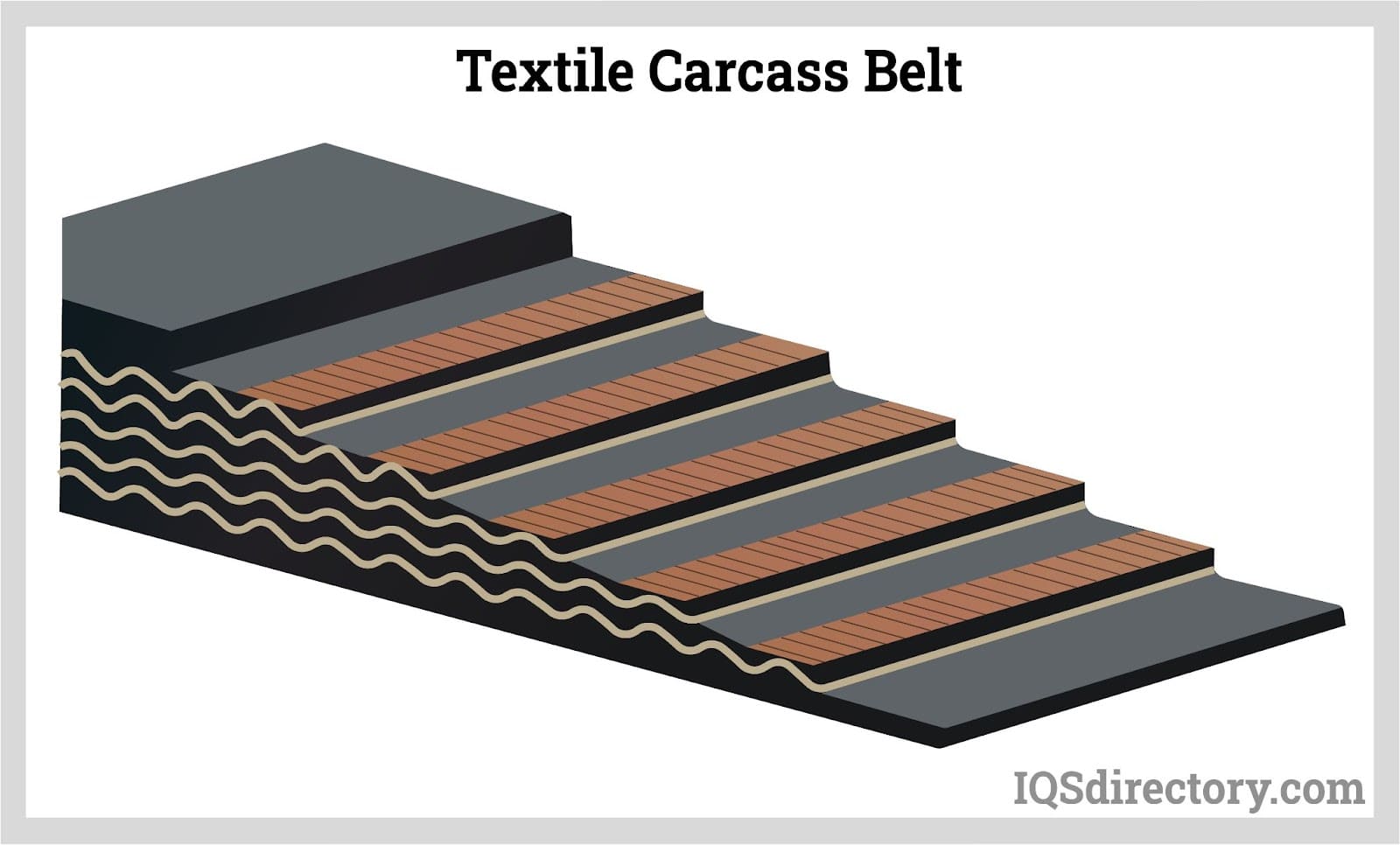

I-Conveyor Carcass

Ekubeni le yi-skeleton yebhanti, kufuneka inikeze amandla okuqina afunekayo ukuhambisa ibhanti kunye nokuqina kwecala lokuxhasa umthwalo.Kufuneka kwakhona ikwazi ukufunxa impembelelo yokulayisha.Ibhanti yiluphu ngoko kufuneka idityaniswe;oku kwaziwa ngokuba yi-splicing.Ngenxa yokuba ezinye zeendlela zokuqhawula zifuna ukusetyenziswa kweebholiti kunye ne-fasteners, isidumbu kufuneka sikwazi ukubonelela ngesiseko esaneleyo kunye nesiqinileyo kwezi zibophelelo.

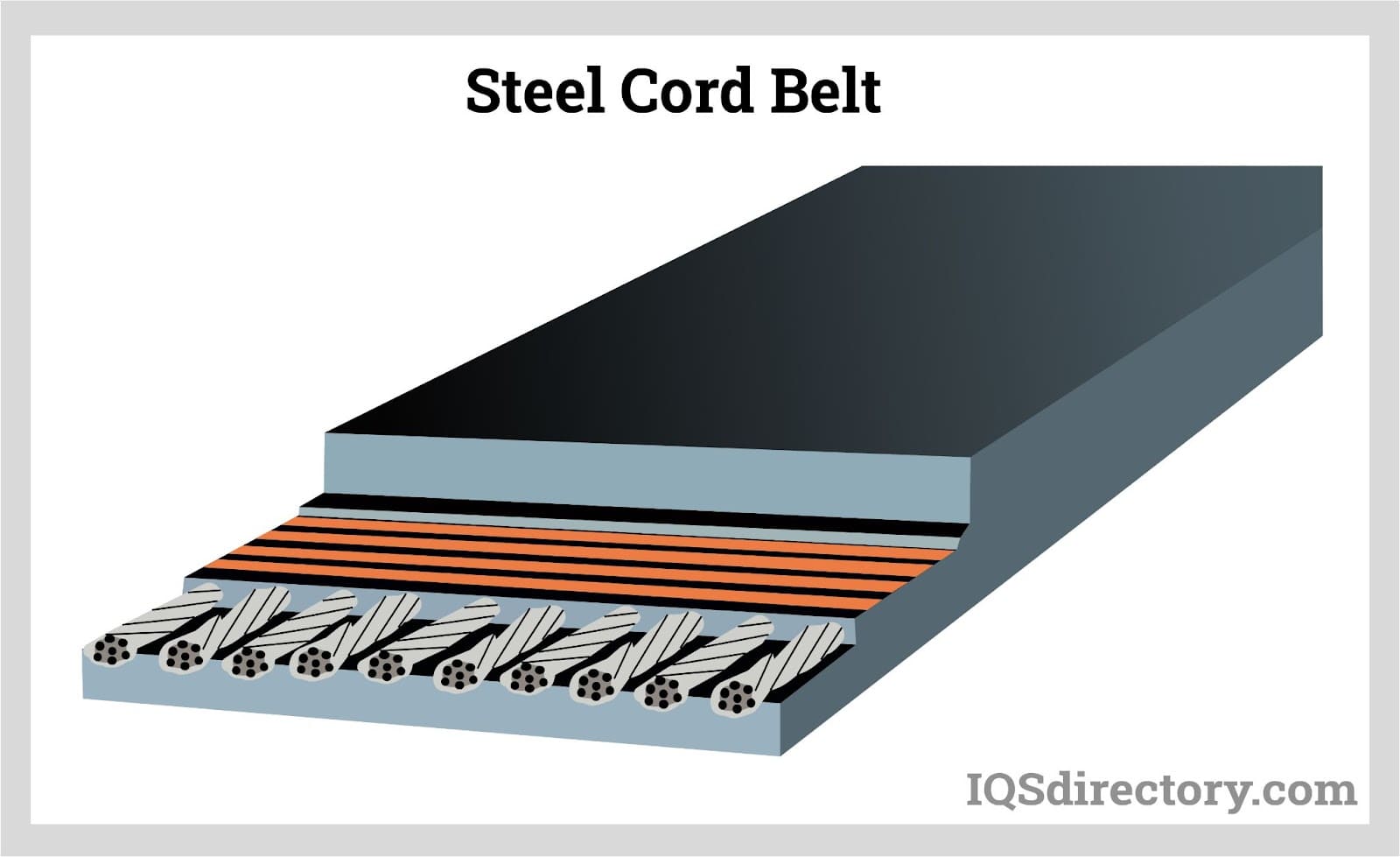

Isidumbu senziwe ngokuqhelekileyo ngentambo yentsimbi okanye i-textile ply.I-textile ply yenziwe ngeentsinga ezifana ne-aramid, i-polyamide, kunye ne-polyester.Ukuba kusetyenziswe i-ply enye kuphela, i-PVC-coated textile carcass ixhaphakile.Izilwanyana ezifileyo zinokuba nemigangatho emithandathu enye kwenye.I-carcass ingabandakanya ukukhuselwa komphetho ofunekayo kakhulu kwiibhanti zokuhambisa ezininzi.

Izigqubuthelo zeConveyor (Phezulu nasezantsi & naMacaleni)

Le yimpahla eguquguqukayo eyenziwe ngerabha okanye iPVC.Amagquma atyhileka ngokuthe ngqo kwizinto zemozulu kunye nendawo yokusebenza.Uqwalaselo ngononophelo lwamaqweqwe kufuneka lwenziwe ngokuxhomekeke kusetyenziso olucetywayo.Oku kulandelayo ngokuqhelekileyo kufuna ingqalelo, ukumelana nomlilo, ukumelana nobushushu obuphantsi, ukuxhathisa igrisi kunye neoli, i-anti-static, kunye nebakala lokutya.

Icala elithweleyo lokuhambisa ngokuxhomekeke kumthwalo, i-angle yokuthambekela komqhubi, kunye nokusetyenziswa ngokubanzi kwebhanti zonke zineempawu ezikhethekileyo.Isenokuba ngamacangci, igudile, okanye icocwe.

Ezinye izicelo ezifana nokuhambisa izinto ezilahliweyo koomatshini be-CNC ziya kuqesha ibhanti yentsimbi kuba oku kunganxibi njengokuba ezinye izinto eziqhelekileyo ziya kwenza.

Kumashishini okulungisa ukutya, iPVC, PU, kunye neebhanti zePE nazo zisetyenziselwa ukugcinwa kokutya kunye nokunciphisa ungcoliseko.

Iibhanti zePlastiki zintsha ngokufanelekileyo, nangona ngenxa yeenzuzo zabo ezinkulu, ngokuthe ngcembe ziba namandla.Zilula ukuzicoca, zineqondo lobushushu elibanzi, kwaye zineempawu ezintle zokulwa ne-viscosity.Zikwayakwazi ukumelana ne-asidi, ukumelana nezinto zealkaline, kunye namanzi etyuwa.

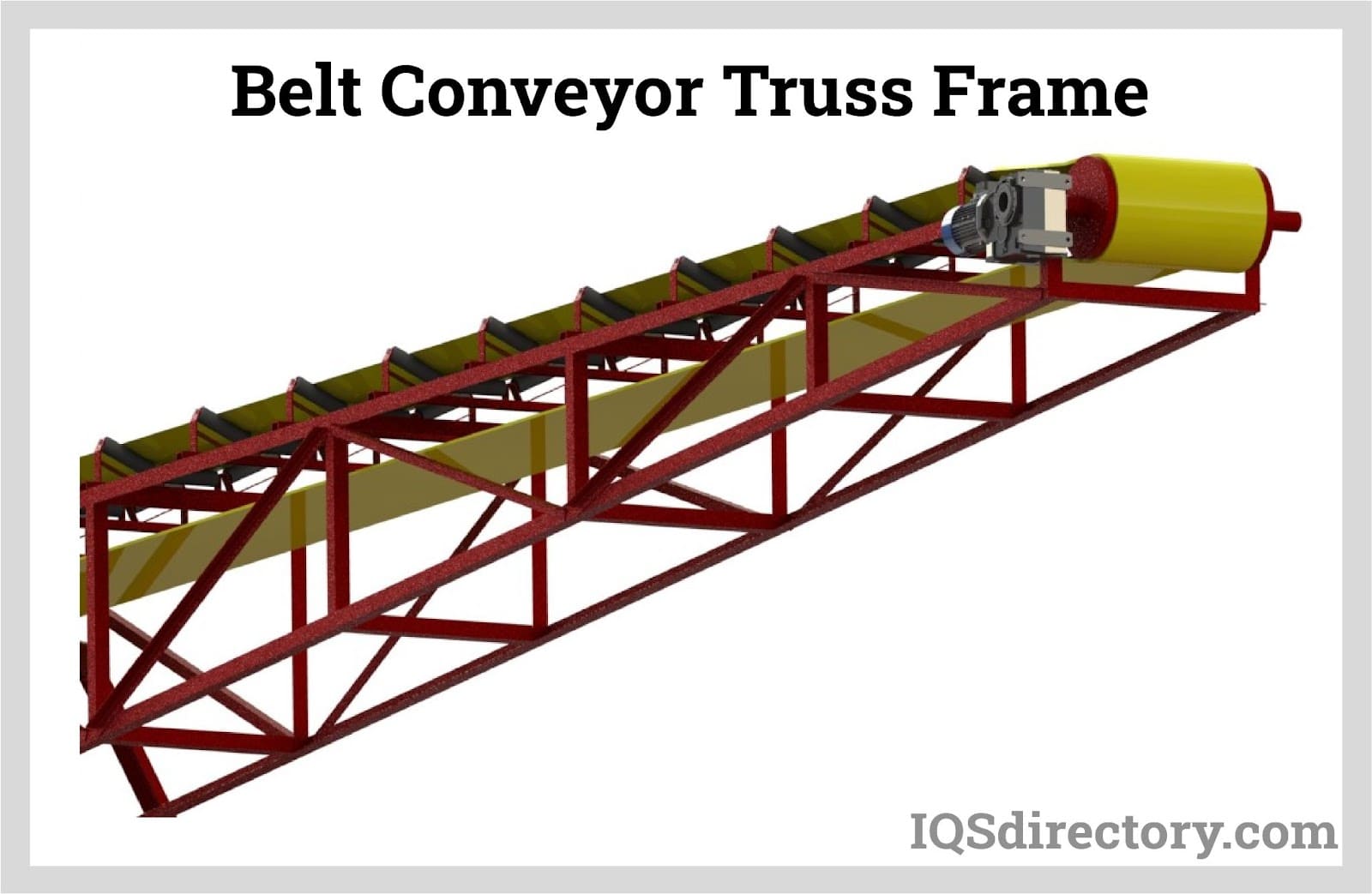

Isakhelo seConveyor

Isakhelo, ngokuxhomekeke kumthwalo, ubude bokusebenza, kunye nomgama oza kugqunywa uya kwahluka.Banokuza kwi-setup elula enokuthi imelwe yi-cantilever.Ziyakwazi nokuba ziitrasi kwimeko yemithwalo emikhulu.I-Extrusions ye-Aluminiyam nayo isetyenziselwa imisebenzi elula kunye nekhaphukhaphu.

Uyilo lwesakhelo ngumba obalulekileyo woyilo lokuhambisa.Isakhelo esiyilwe kakubi sinokubangela:

- Ibhanti liphelelwa ngumkhondo

- Ukusilela kolwakhiwo kubangela ukuba:

- Amaxesha amade aphantsi aguqulela ukulibaziseka kwimveliso

- Ukwenzakala kunye nokwenzakala

- Ukuchithwa kweendleko

- Iindlela zokwenziwa ezixabisa kakhulu kunye nofakelo.

Kwisakhelo, ezinye izincedisi zinokuxhonywa njengeendlela zokuhamba kunye nokukhanya njengoko kubonisiwe ngasentla.Iimeko zokukhanyisa ziya kufuna iishedi kunye noonogada ukukhusela izinto eziphathekayo.

Ukulayishwa kunye nokukhupha ii-chutes nazo zinokuxhonywa.Ulwazi lwazo zonke ezi zongezelelo ezinokwenzeka zibalulekile ukuphepha ukugcwala okungabalwanga.

Isahluko 2: Iindidi zeIiConveyors zebhanti

Esi sahluko siza kuxoxa ngeentlobo zokuhambisa amabhanti.Ezi ziquka:

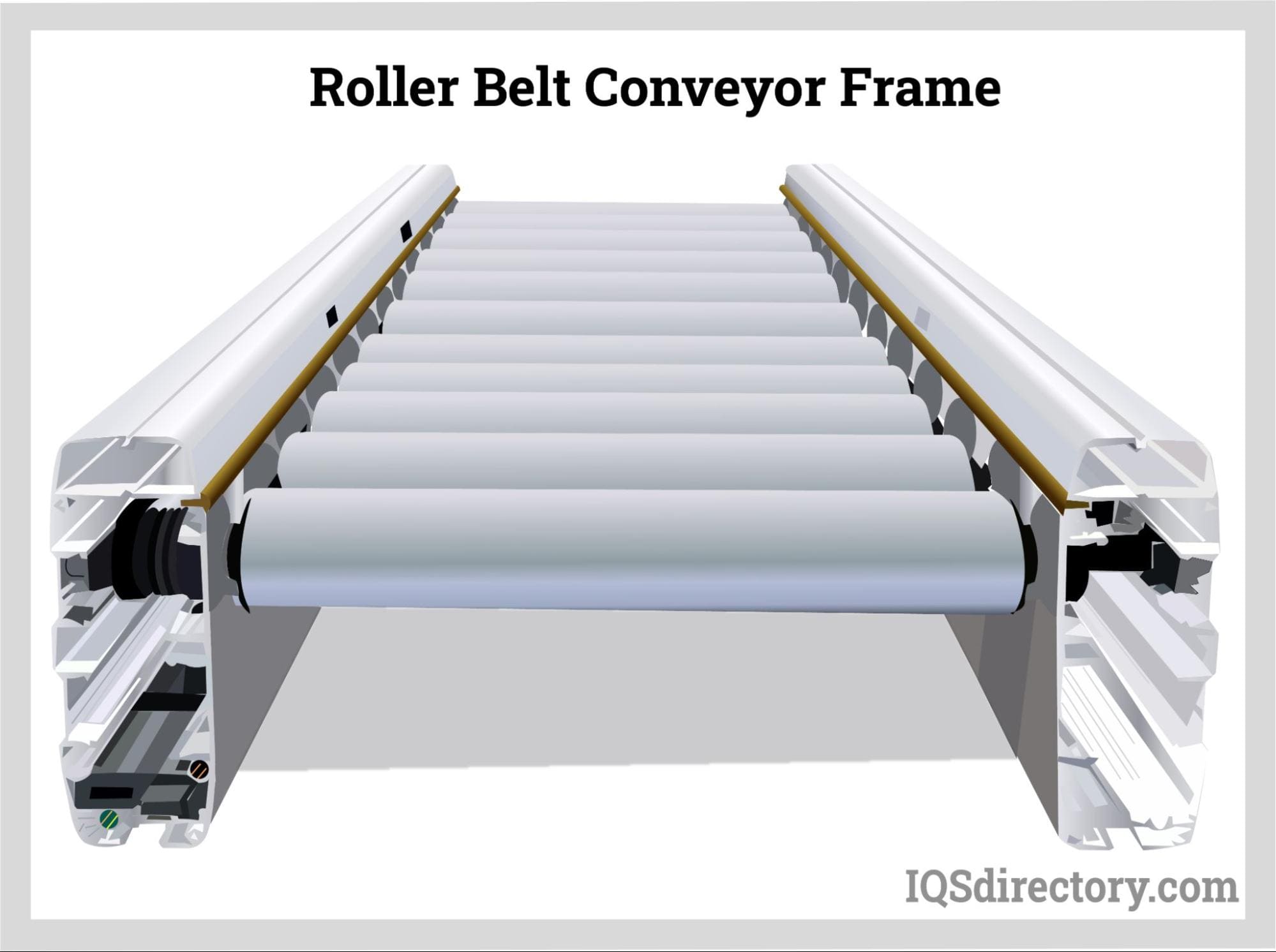

I-Roller Bed Belt Conveyor

Umphezulu ongaphantsi kwebhanti kule nguqulo yebhanti yokuhambisa yenziwe ngoluhlu lwee-roller.Iirola zifakwe ngokusondeleyo ukwenzela ukuba kungabikho ukugoba kwebhanti.

Zifanelekile zombini kunye nokuhanjiswa komgama omfutshane.Kwezinye iimeko, banokuba mfutshane kangangokuba baqeshe kuphela iirola ezimbini zenkqubo yonke.

Xa usebenzisa i-gravity ukulayisha, i-roller belt conveyor yenye yezona ndlela zingcono zokukhetha.Ukuba umntu usebenzise ukulayisha ngesandla, ukothuka kuya konakalisa iirola ngokulula kuba zihlala zineebheringi zangaphakathi.Ezi bheringi kunye nomphezulu ogudileyo jikelele we-roller zinciphisa kakhulu ukukhuhlane okwenza kube lula ukuhambisa.

Izithuthi zebhanti eziqengqelekayo zisetyenziswa ikakhulu apho kukho ukuhlelwa, ukudibanisa, ukuthuthwa nokuhlolwa ngesandla.Imizekelo ibandakanya:

- Ukuphatha imithwalo kwisikhululo seenqwelomoya

- Ukuhlelwa kwezinto ezithunyelwa ngeposi kuquka neeofisi zeposi

I-Flat Belt Conveyor

Ibhanti elisicaba lokuhambisa yenye yezona ntlobo zixhaphakileyo zokuhambisa.Ngokuqhelekileyo isetyenziselwa ukuthutha izinto ngaphakathi kwendawo.Ukuhanjiswa kwangaphakathi kufuna uthotho lweerola/ iipuli eziqhutywa ngamandla ukutsala ibhanti.

Iibhanti ezisetyenziselwe ukuhambisa ibhanti elisicaba ziyahluka ukusuka kwilaphu, kunye neepolymers ukuya kwiirubha zendalo.Ngenxa yoku, iba yinto eguquguqukayo ngokubhekiselele kwizinto eziza kuhanjiswa.Kwakhona kulula kakhulu ukulungelelanisa kunye ne-pulley yomsila ngokuqhelekileyo ifakwe ukuze ikwazi ukulungiswa ukulungelelanisa ibhanti.Ngokuqhelekileyo libhanti lokuhambisa elinesantya esisezantsi.

Izicelo zokuhambisa ibhanti elisicaba ziquka:

- Imigca yokuhlanganisa ecothayo

- Ukuhlamba izicelo

- Indibano yemizi-mveliso enothuli olukhanyayo

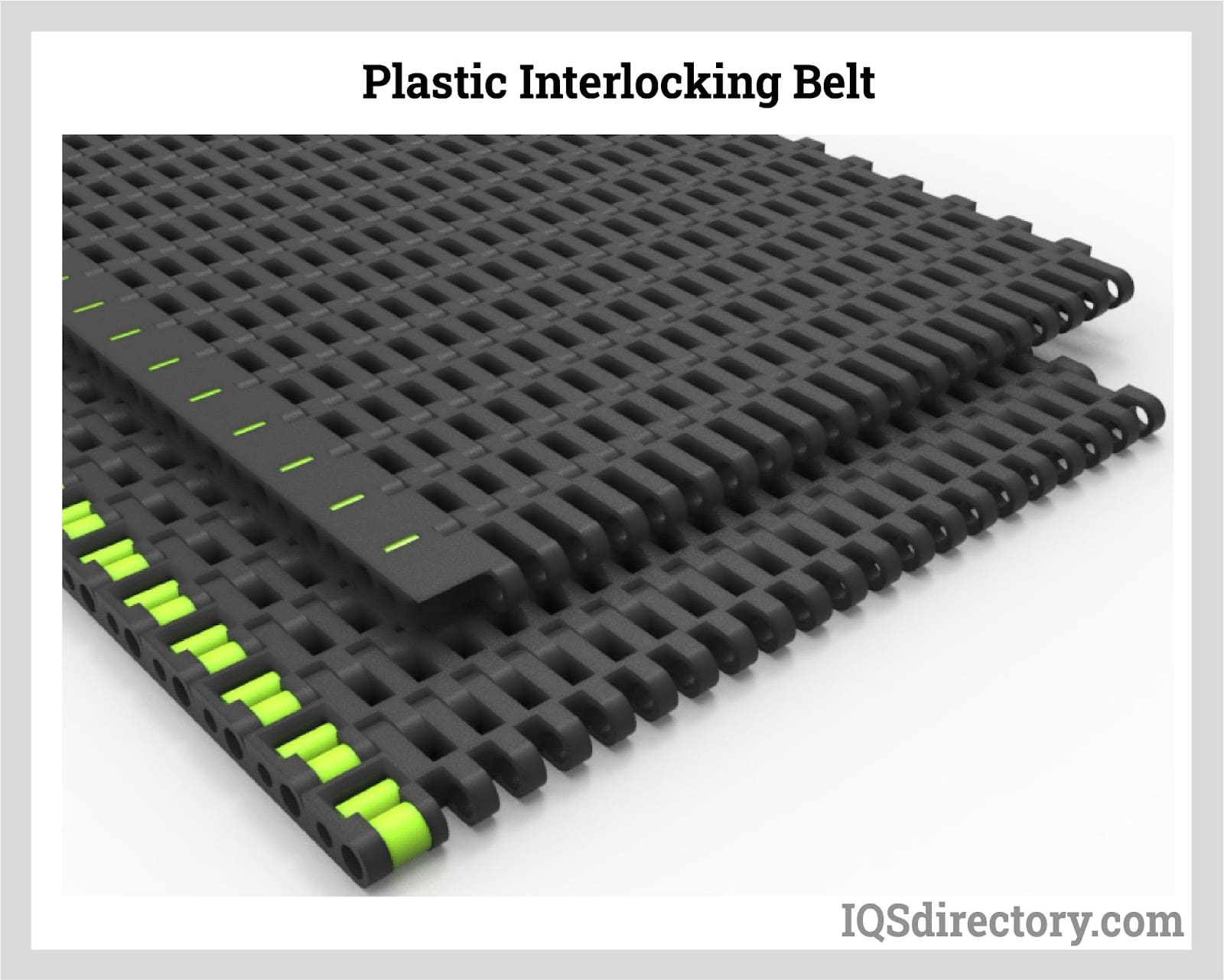

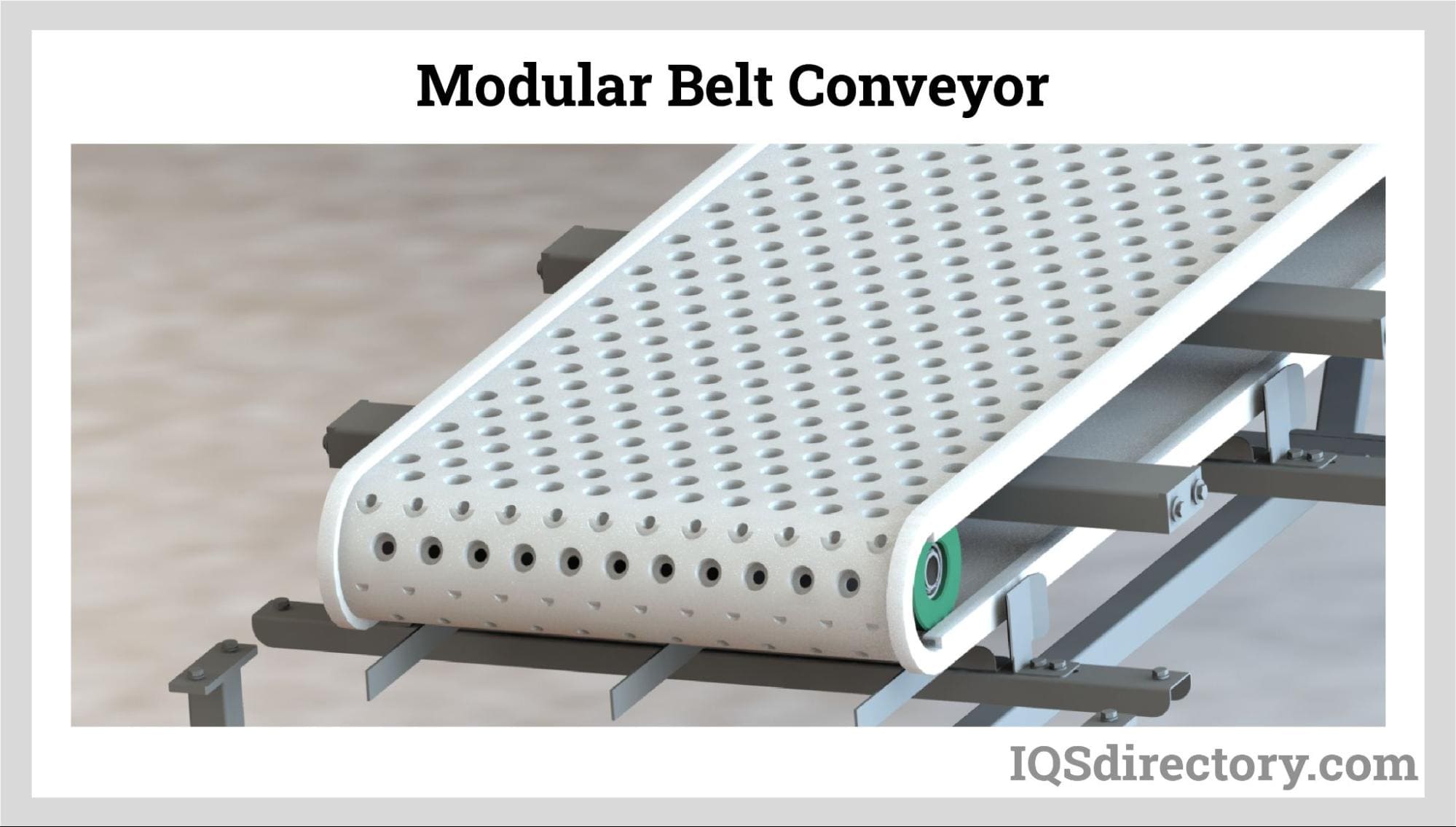

I-Modular Belt Conveyor

Ngokwahlukileyo kubahambisi bebhanti abathe tyaba abasebenzisa i-loop "engenamthungo" yebhanti eguquguqukayo, i-Modular Belt conveyors isebenzisa uluhlu lweziqwenga eziqinileyo ezidibeneyo eziqhelekileyo ezenziwe ngeplastiki okanye isinyithi.Zisebenza ngakumbi njengetsheyini lisenza kwibhayisekile.

Oku kubanika inzuzo enkulu ngaphezu koogxa babo bebhanti ebhetyebhetye.Ibenza babe rhabaxa kuba banokusebenza kuluhlu olubanzi lwamaqondo obushushu kunye namanqanaba e-PH.

Xa icandelo lebhanti lonakaliswa, umntu unokutshintsha ngokulula elo candelo lilodwa kunokuba amabhanti aguquguqukayo apho ibhanti liza kufuneka litshintshwe.Iibhanti zemodyuli zinokuhamba, zisebenzisa imotor enye kuphela, zijikeleze iikona, imigca ethe tye, ukuthambeka, kunye nokwehla.Njengokuba abanye abahambisi benokwenza okufanayo, kuza kwiindleko zobunzima kunye nemali.Kwizicelo ezinokuthi zifune ububanzi "obungaqhelekanga" obukhulu kunobude, okanye uhlobo lokuhambisa, abahambisi bebhanti beemodyuli bayakufezekisa oko kulula kakhulu.

Kuba ingeyiyo intsimbi, kulula ukuyicoca, kwaye ingenarhasi kwirhasi kunye nolwelo, iimodyuli zebhanti zokuhambisa zingasetyenziswa apha:

- Ukuphatha Ukutya

- Ukuphatha ulwelo

- Ukufunyanwa kwesinyithi

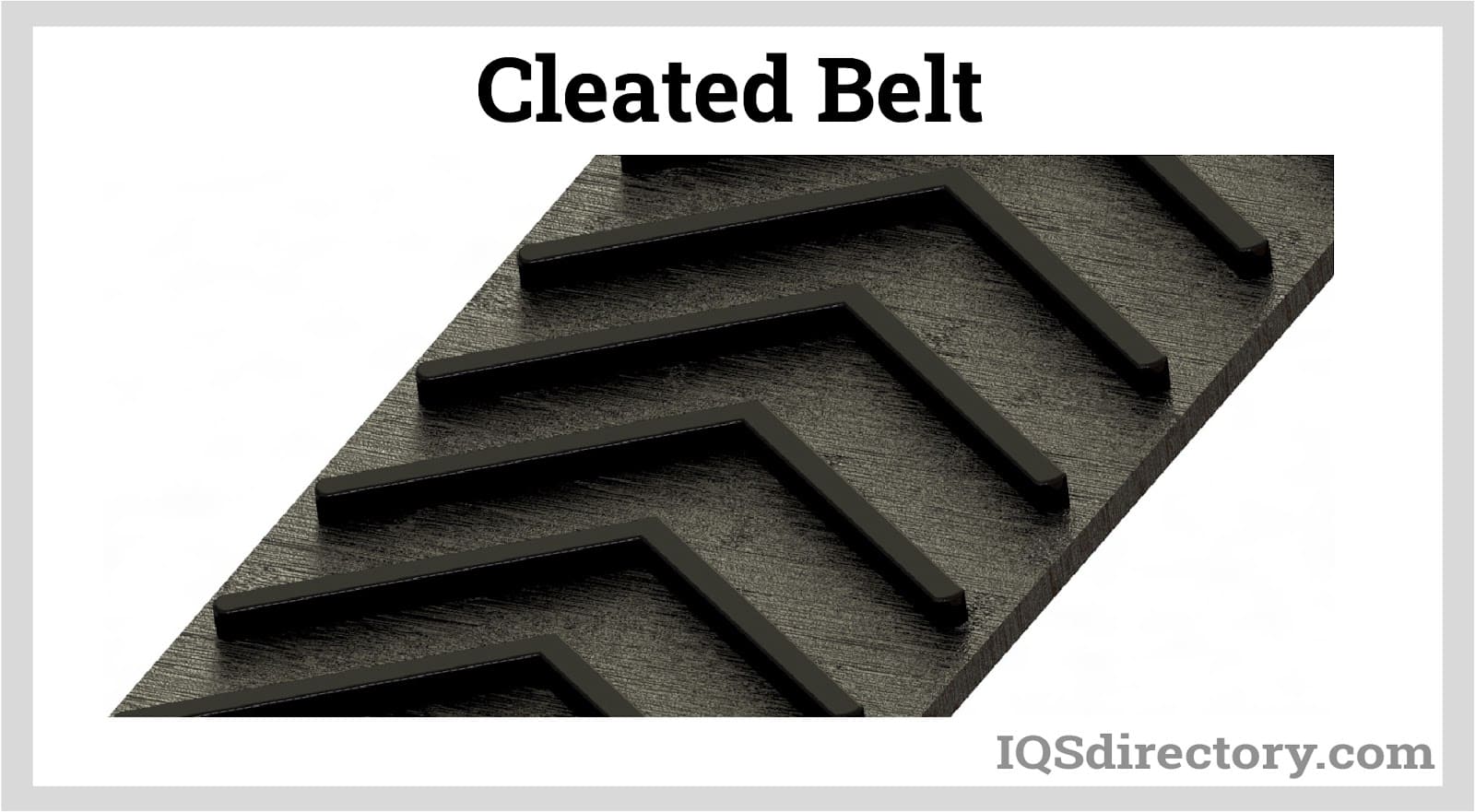

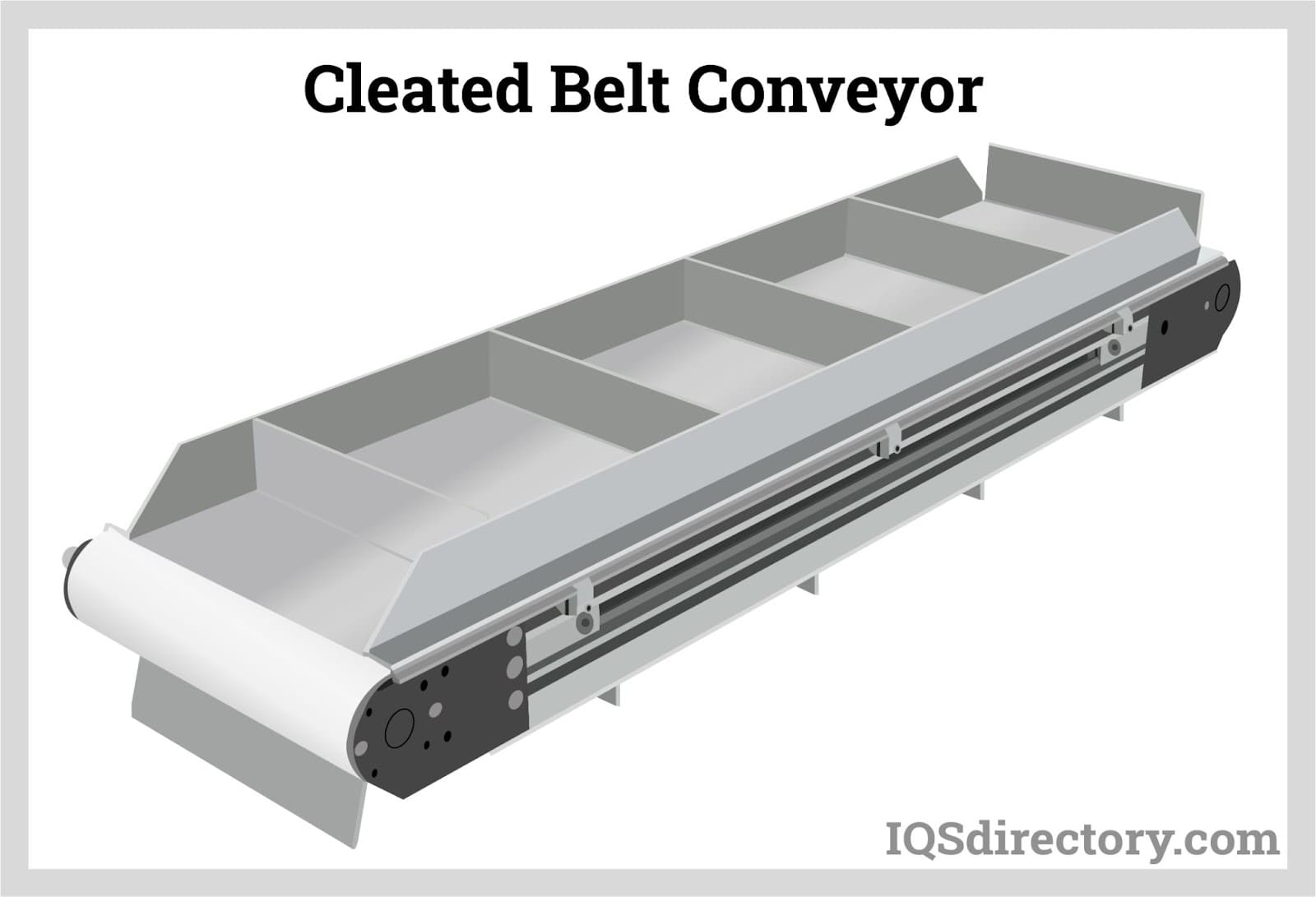

I-Cleated Belt Conveyor

Abahambisi bebhanti abacinyiweyo baya kuhlala benomqobo okanye becocekile kuyilo lwabo.I-cleats isebenza ukwahlula amacandelo alinganayo kwibhanti.La macandelo agcina amasuntswana kunye nemathiriyeli enokuthi ngenye indlela ibuyele umva okanye iwe kumhambisi ngexesha lokuhamba kunye nokuncipha.

I-cleats iza kwiimilo ezahlukeneyo kunye nobukhulu obuquka:

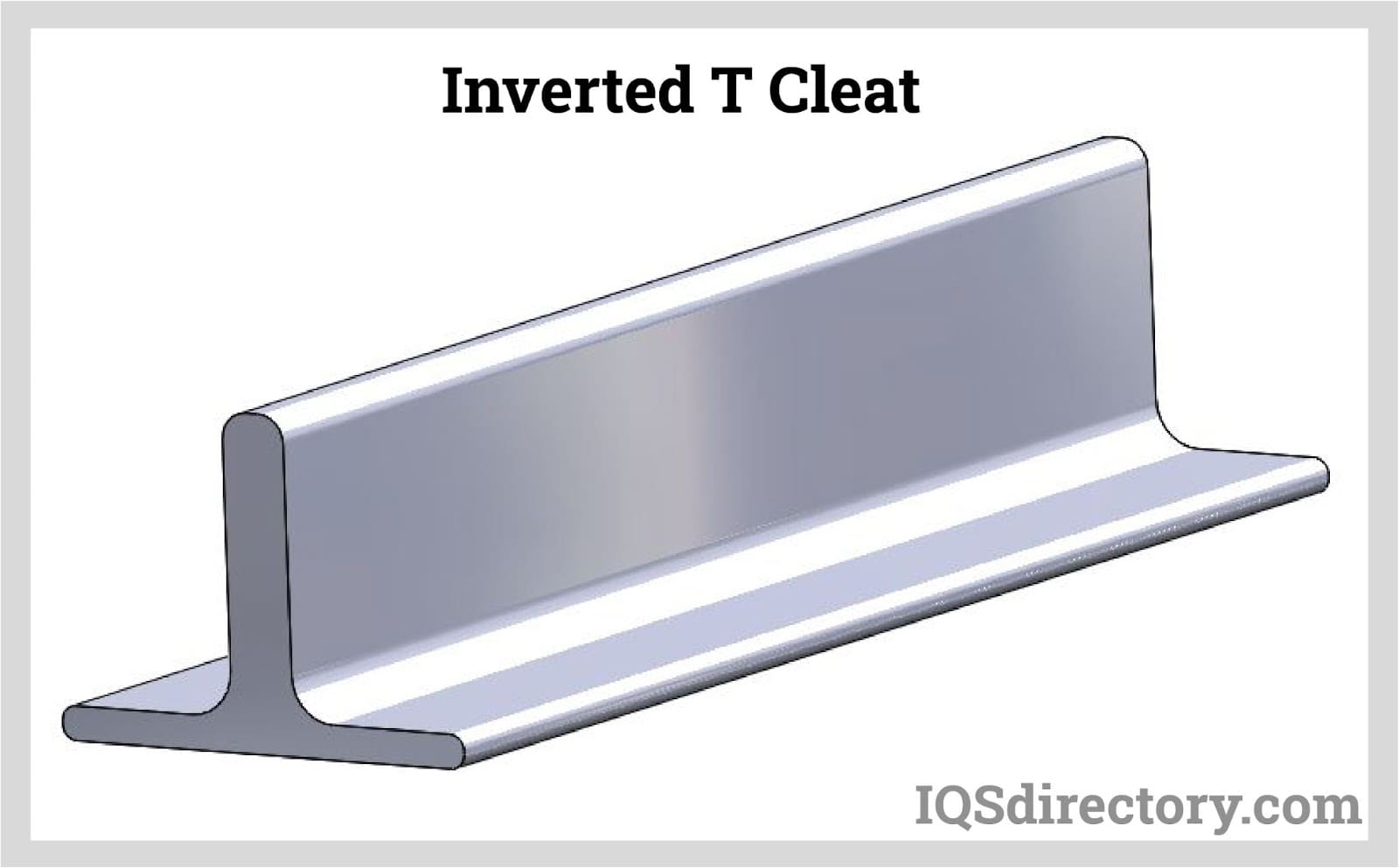

I-Capital eguqulweyo T

Le cleat iya kuma kwii-degrees ezingama-90 ukuya kwibhanti ukunika inkxaso kunye nokuguquguquka kwizinto ezibuthathaka.Ifaneleka kakhulu ukwenza imisebenzi elula kunye nokuphatha iindawo ezincinci, iimpahla ezipakishweyo, kunye neemveliso zokutya.

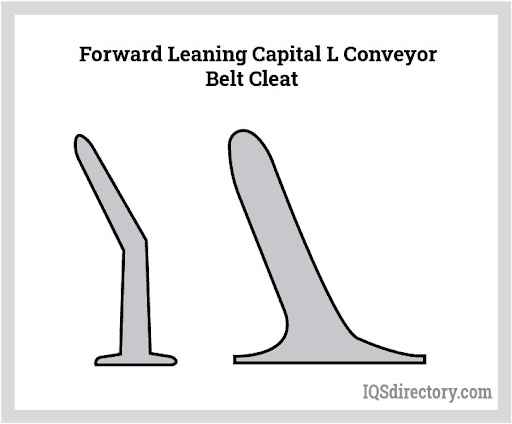

Phambili-Inkunzi eYayame phambili L

Ngenxa yokuma kwayo, inokuxhathisa ngokulula amandla anamandla.Ingasetyenziselwa ukukha iigranuli kwaye uzibambe ngokuchasene nomxhuzulane.Ingasetyenziswa ukubamba ukukhanya ukuya kwigranule ezinobunzima obuphakathi.

I-V Cleats eguqulweyo

Ezi ngcango zingaphantsi kwe-5cm ubude ukuze zibe nefuthe elifanayo nelo lomkhombe.Zingasetyenziselwa ukuthutha izixa enzima okanye ezinkulu zemathiriyeli ngenxa yokwaleka kwazo okufutshane, ezinokumelana neempembelelo eziphezulu.

Izikhonkwane kunye nezikhonkwane

Ezi zicwecwe zisetyenziselwa ukunceda ukuphuma kolwelo emva kokuhlamba izinto ezifana nemifuno kunye neziqhamo.Izikhonkwane kunye nezikhonkwane yindlela engabizi kakhulu yokuhambisa izinto kunye nezinto ezingadingi nkxaso kubude bebhanti ezifana neebhokisi ezinkulu okanye iintonga.Zisenokusetyenziswa ukuhambisa ngokukhetha iimveliso ezigqithisa ubungakanani obufunwayo kwaye zide zibambe imveliso enye endaweni.

Olunye usetyenziso lwee-Cleated Belt Conveyors ziquka:

- Iziteshi ezizihambelayo luhlengahlengiso lwabahambisi bebhanti abacociweyo ngengqiqo yokuba bathwala izinto ezikhululekileyo benyuka benyuka kwindawo engumnqantsa.

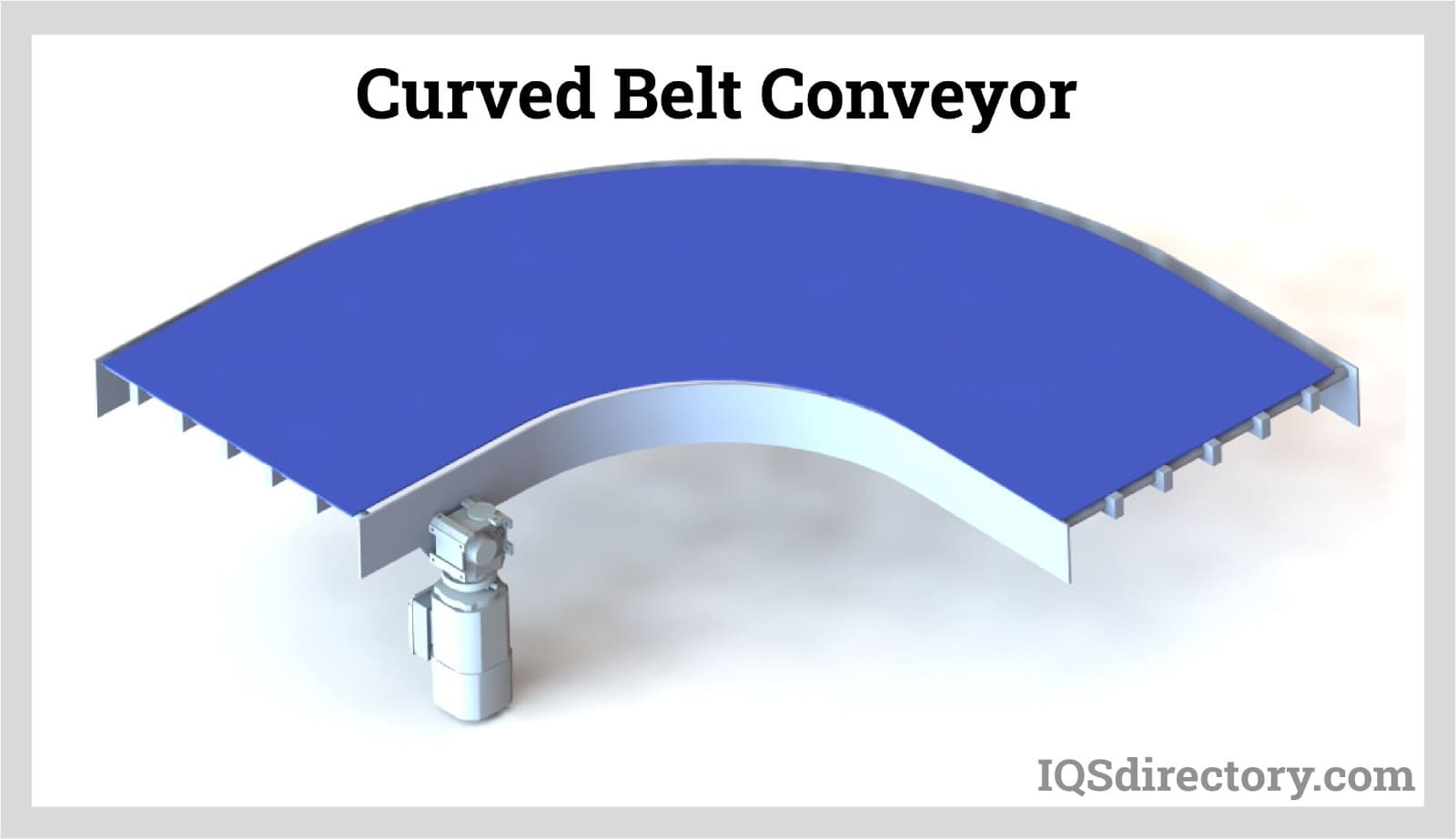

Ibhanti eligobileyo leConveyor

Lo mhambisi usebenzisa isakhelo esenziwe ngelaphu nesele sigobile ukuze sithwale izinto zijikeleze iikona ezixineneyo.Isetyenziswa apho isithuba sinqongophele kwaye abahambisi abajikajikayo banokugcina indawo.Iigophe zinokuhamba umnqantsa ukuya kuthi ga kwi-180 degrees.

Iiplastiki zemodyuli ezinamacandelwana adityanisiweyo ziyasetyenziswa kodwa kuphela ukuba umhambisi unomsebenzi othe ngqo phambi kokuba ajike.Amabhanti athambileyo athambileyo aya kusetyenziswa ukuba ibhanti ngokuyintloko igobile.

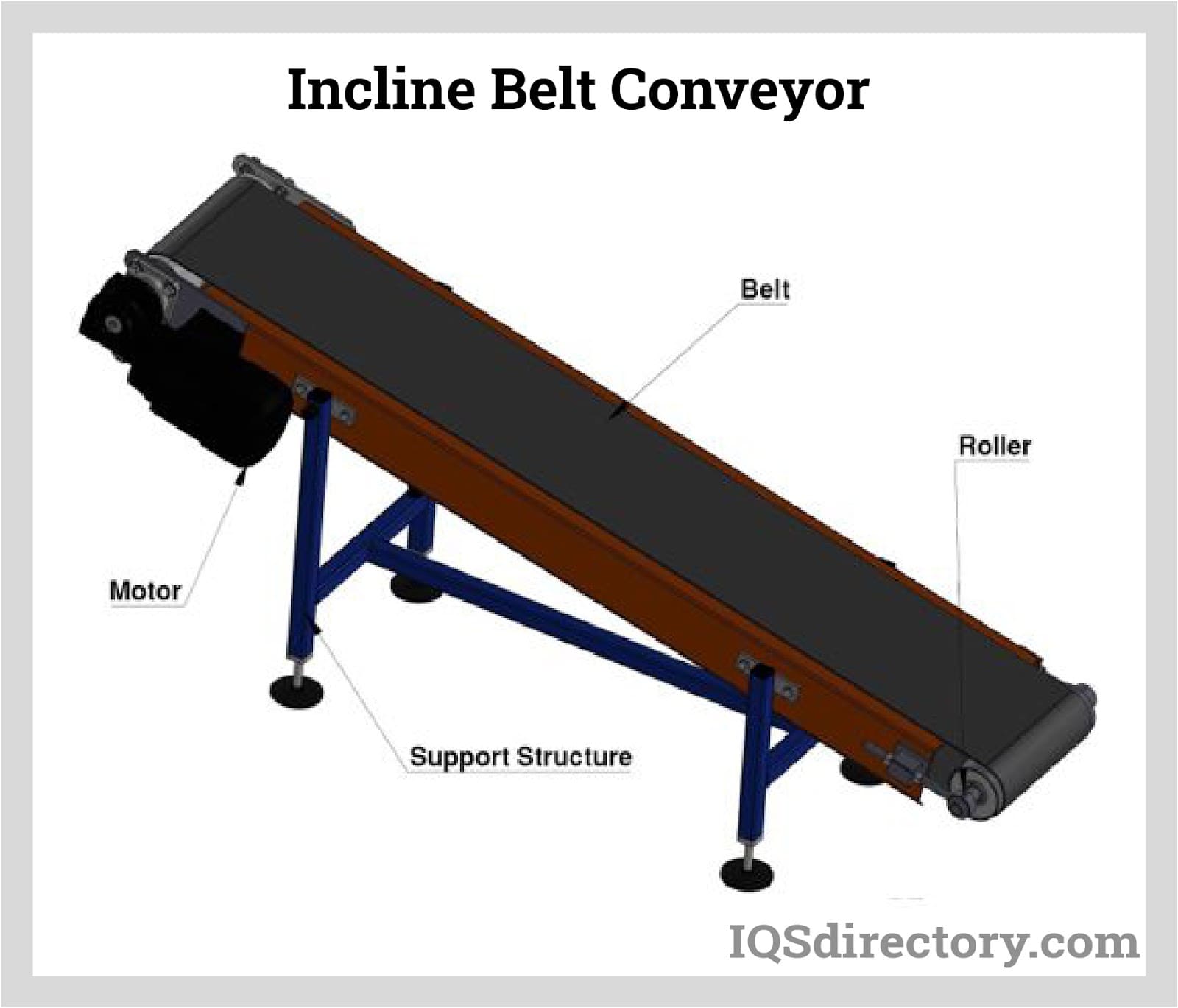

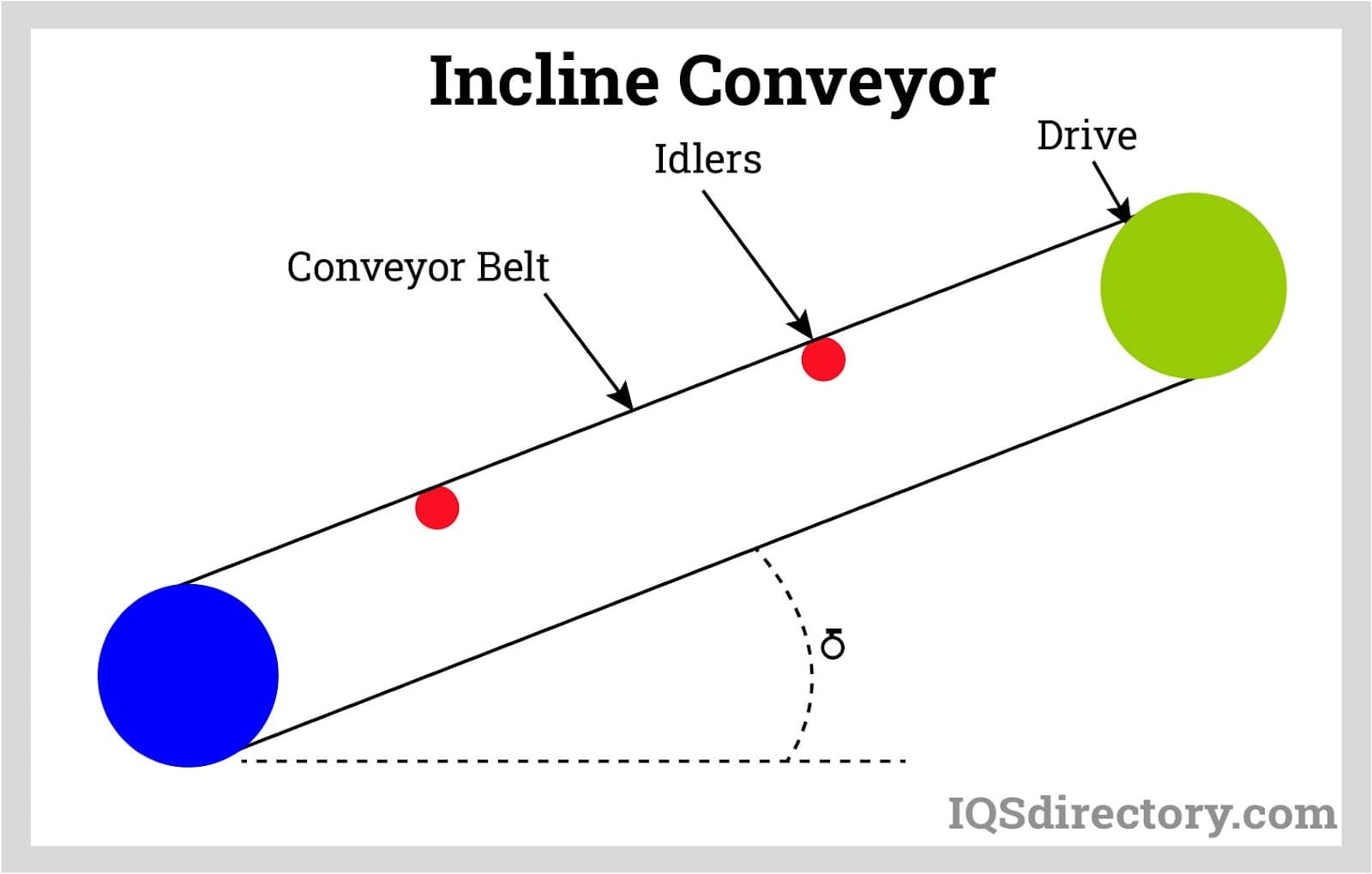

Nciphisa/Yehla i-Conveyor yebhanti

Abahambisi bokuhambisa badinga amandla angqongqo oxinzelelo, itorque ephezulu, kunye nokutsala kumphezulu webhanti ukuthintela izinto ekuweni kwibhanti yokuhambisa.Ke, baya kubandakanya injini yegiya, indawo yokuqhubela phambili, kunye nokuthatha.Ibhanti kufuneka ibe nomphezulu orhabaxa ukuvumela ukutsaleka okukhulu.

Njengabahambisi abacoliweyo, ezi nazo zithwala izinto zinyusa igradient zingavumeli ukuba izinto ziwe.Zisenokusetyenziswa ukunyusa umxhuzulane wokuhamba kolwelo.

UGutyulo loGutyulo loGutyulo

Kwimizi-mveliso yamayeza kunye nokutya, ukuvala inzala kunye nokuhlanjwa rhabaxa kudla ngokufuneka ukuba kwenzeke, ngokuhambelana nezikhokelo zempilo nezokhuseleko.Ukuhlamba kunye nokuhanjiswa kococeko kuyilelwe ukuphatha iinkqubo zococeko ezilolo hlobo.Amabhanti asetyenziswa apha adla ngokuba ziibhanti ezisicaba ezibhityileyo.

Izihambisi zebhanti zokuhlamba ezicocekileyo zisetyenziswa kwizinto ezisuka kumaqondo obushushu agqithisileyo njengezikhenkcezisi kunye neziko.Ngamanye amaxesha kufuneka basebenze kwioli eshushu okanye i-glaze.Ngenxa yendlela abanokuphatha kakuhle ngayo imeko-bume enamafutha, ngamanye amaxesha isetyenziselwa ukukhuphela imigqomo yeoli kunye neekhreyithi ezinqanaweni.

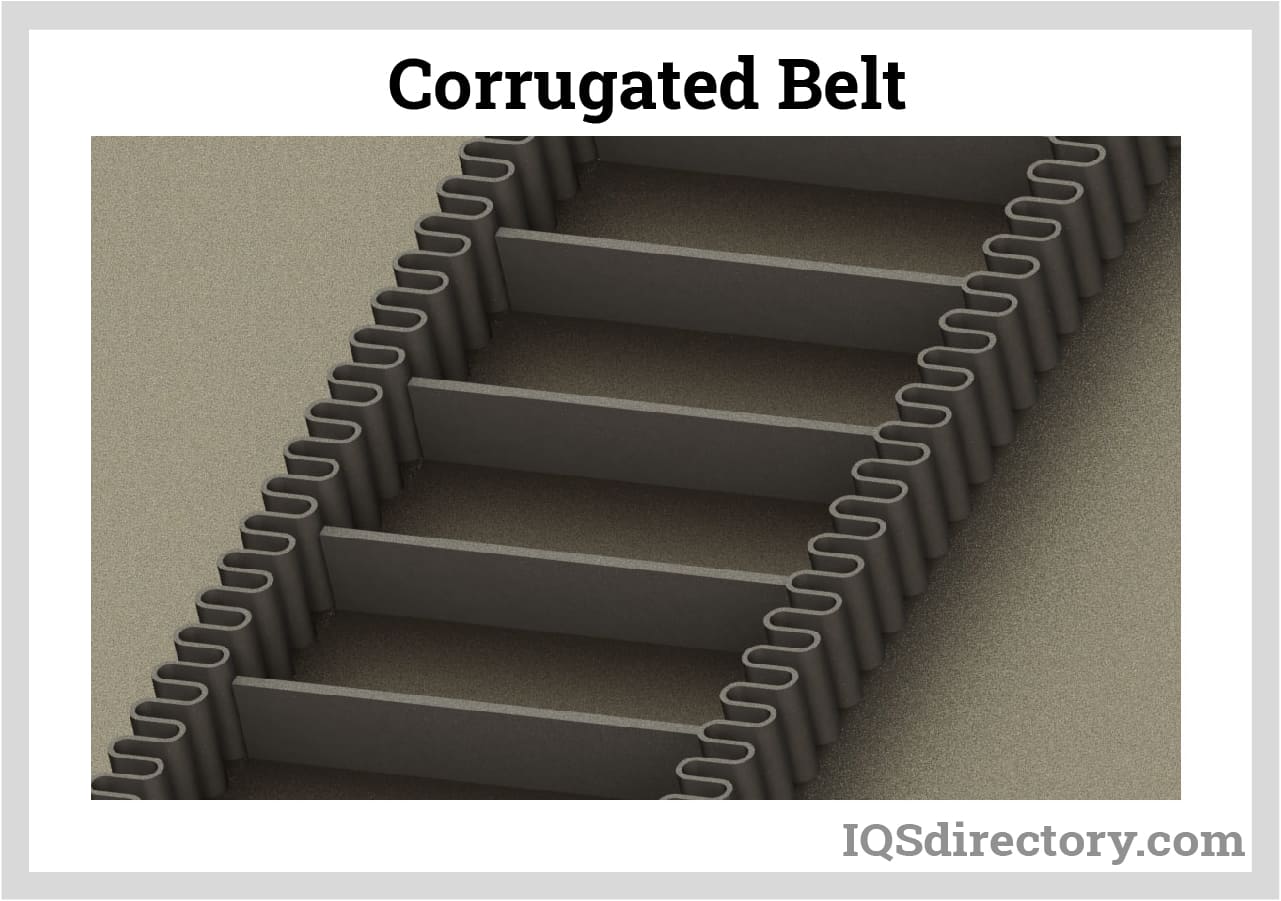

Ii-Conveyors eziQhahliweyo

Ibhanti elihambisa ibhanti ayiloluhlobo lwahlukileyo lwebhanti kuba ukukrola kunokufakwa kulo naluphi na uhlobo lokuhambisa.

Isebenzisa ibhanti elenza imilo ekhutshiweyo ngenxa yeerola ezingaphantsi kwayo.

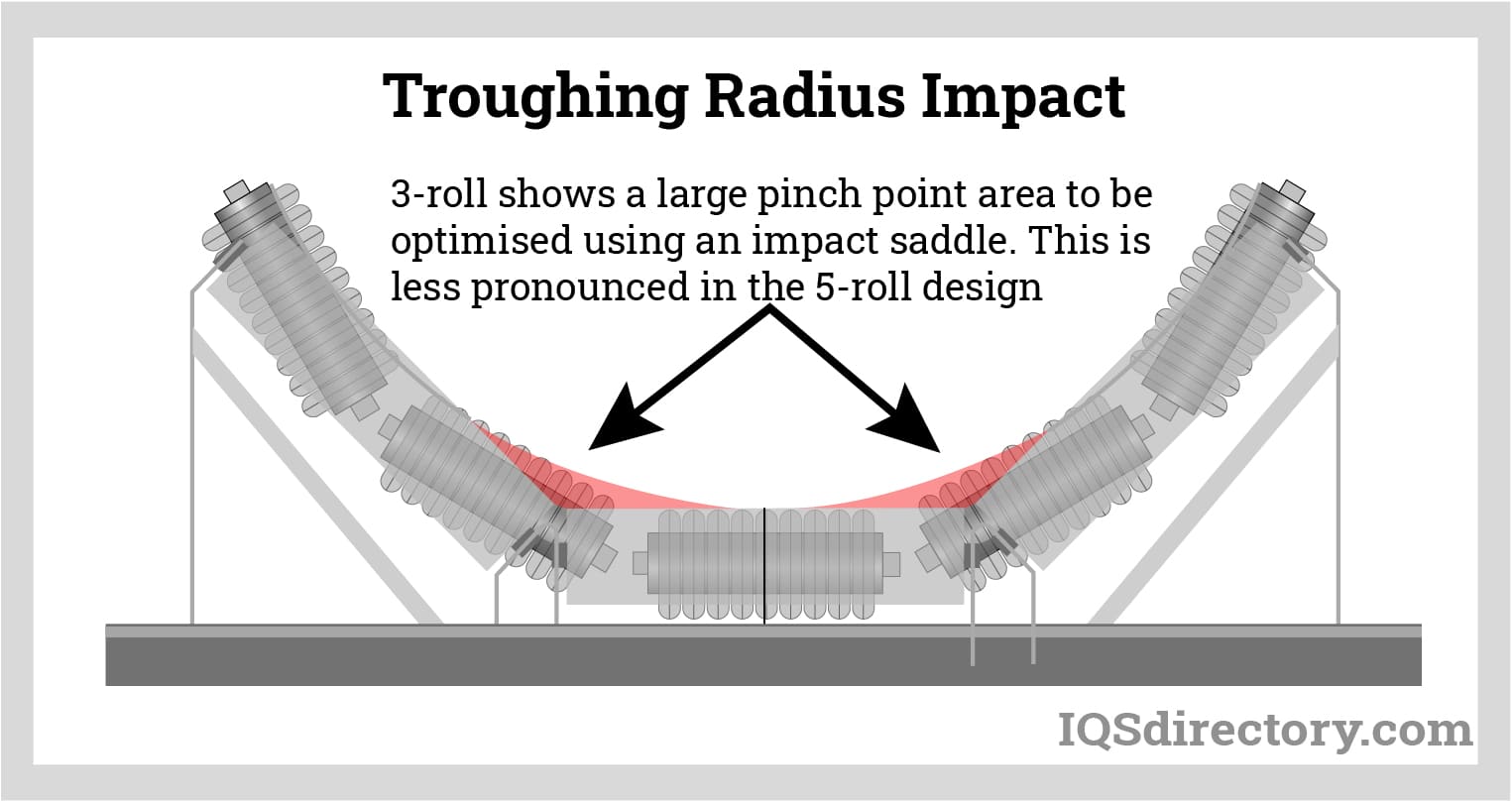

Iirola ezizibhuqayo zine-roller esembindini ene-axis ethe tyaba yokujikeleza, kwaye ii-roller ezimbini zangaphandle (i-wing rollers) zine-axis ephakanyiswe kwi-angle ukuya kwindawo ethe tye.I-engile idla ngokuba malunga nama-25 degrees.Ukucofa kwenzeka kuphela kwiirola eziphezulu ze-idler kwaye azizange zibe sezantsi.

Ii-angles eziphezulu ze-troughing ziya kubangela umonakalo osisigxina kwibhanti.Ukuba ibhanti linyathelwe kwii-angles eziphakamileyo, liya kugcina imilo yekomityi kwaye kuya kuba nzima ukuyicoca, kunzima ukuyilandela kunye nokuphula isidumbu sebhanti.Isenokunciphisa ubungakanani bonxibelelwano lomphezulu kunye neerola ezingasebenziyo, ezithi ekugqibeleni zehlise ukusebenza kakuhle kwenkqubo yokuhambisa ibhanti.

Amabhanti emkhombeni ahlala esebenza kwinqwelomoya enye, ethe tyaba okanye ithe tye, kodwa ityekele ukuya kutsho kuma-25 degrees kuphela.Ibhanti kufuneka libe neradiyasi enkulu ngokwaneleyo ukuze ikwazi ukuchukumisa zonke iirola ezikwindawo engenzi lutho.I-engile ebukhali yokukrola ithetha ukuba ibhanti aliyi kubamba i-roller engasebenziyo esembindini, ngaloo ndlela ijongela phantsi isidima sebhanti kunye nokusebenza kakuhle kwenkqubo yokuhambisa ngokubanzi.

Isahluko sesi-3: Uyilo kunye noKhetho lwee-Belt Conveyors

Xa uyila ibhanti lokuhambisa, iiparamitha eziphambili ekufuneka ziqwalaselwe zezi:

- Ukukhetha imoto kunye nebhokisi yegiya

- Isantya sebhanti

- Uxinzelelo kunye nokuthatha

- Izinto eziza kuhanjiswa

- Umgama ekufuneka uhanjiswe ngawo

- Indawo yokusebenza umz. ubushushu, ukufuma, njl.

Ukukhetha iMoto kunye nebhokisi yeGearbox

Ukunceda ekukhetheni injini, umntu kufuneka aqale azi ukuba yintoni amandla okutsala asebenzayo afunekayo kumhambisi.

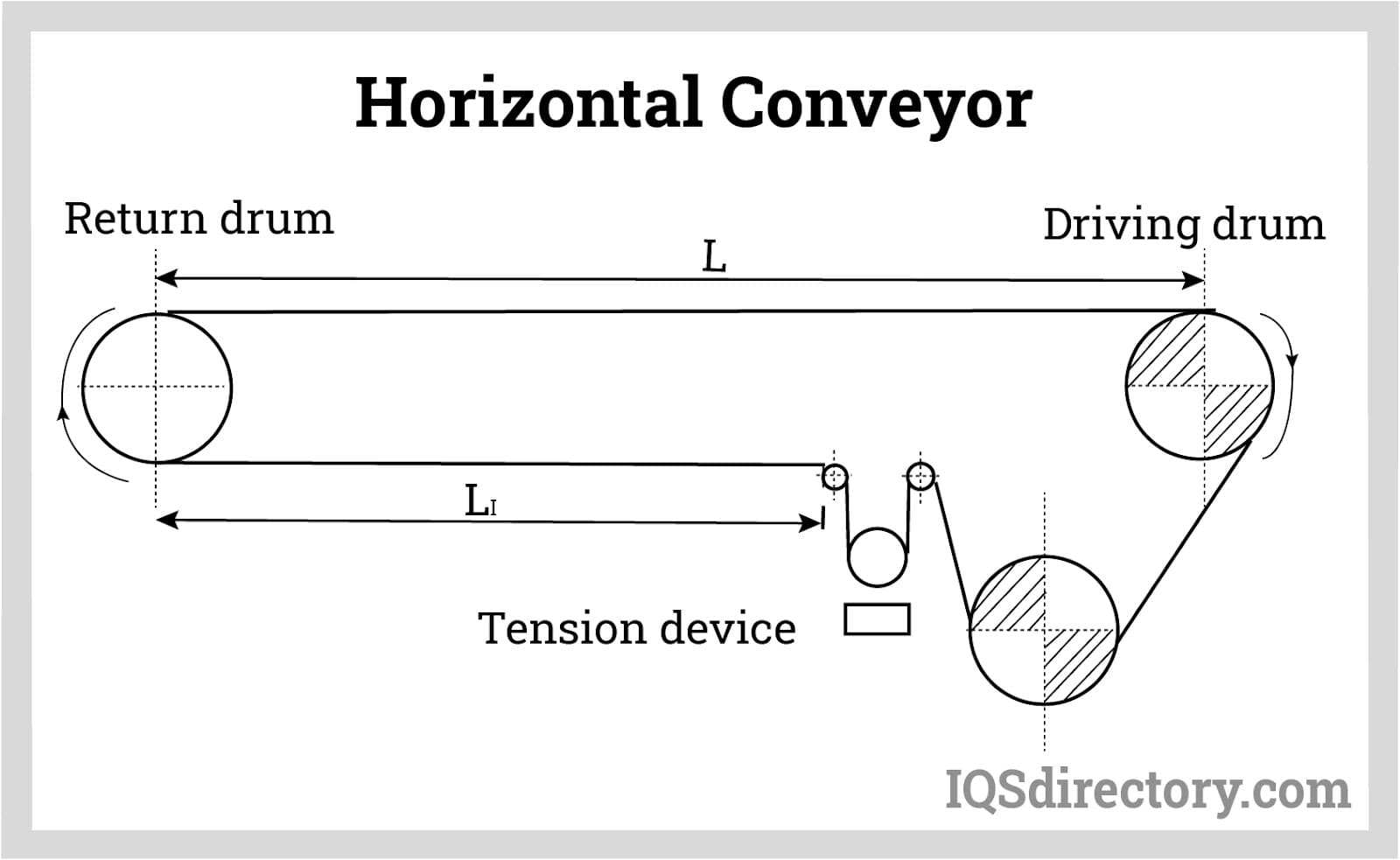

Kumhambisi olula othe tyaba, amandla okutsala asebenzayo anikwa ngale fomula ingezantsi:

Fu=µR*g*(m+mb+mR)

Apho

- Fu = Amandla okutsala asebenzayo

- µR = I-friction Coefficient xa ubaleka phezu kwerola

- g = Isantya esibangelwa ngumxhuzulane

- m = Ubuninzi beempahla ezihanjiswe kubude bonke bomhambisi

- mb = Ubunzima bebhanti

- mR = Ubunzima bazo zonke iirola ezijikelezayo kuthatyathwe ubunzima berola yokuqhuba

Kwinkqubo ekuthambekeni, amandla oTsalo asebenzayo anikwe ngolu hlobo lungezantsi:

Fu=µR*g*(m+mb+mR)+gmsina

Apho

- Fu = Amandla okuTsala asebenzayo

- µR = I-friction Coefficient xa ubaleka phezu kwerola

- g = isantya ngenxa yomxhuzulane

- m = ubunzima bempahla ethunyelwe kubo bonke ubude bomhambisi

- mb = Ubunzima bebhanti

- mR = Ubunzima bazo zonke iirola ezijikelezayo kuthatyathwe ubunzima berola yokuqhuba

- α = I-engile yokuthambekela

Nje ukuba amandla okutsala eqinisekisiwe, kuba lula ukuza netorque kwaye kungoko imotor enokusetyenziswa kwaye i-gearbox iya kulandela emva kwayo.

Isantya seConveyor

Isantya somthumeli siya kuba siseko sepuli yokuqhuba iphindaphindwe ngokujikela ngexesha leyunithi.

Vc=DF

- Vc = Isantya sebhanti yokuhambisa kwi-ms-1

- D = Ububanzi be-pulley yokuqhuba kwiimitha.

- F = Ukuguqulwa kwepuli yokuqhuba ngesekhondi

Shumision kunye nokuThatha iBhanti

Ukuthatha icandelo elibalulekileyo ekugcineni nasekufezekiseni uxinezeleko lwebhanti.Oku kuya kuba negalelo elikhulu kwinkqubo kunye nokuzinza kwayo koomatshini.

Ibhanti elibophene ngokufanelekileyo liya kunxiba ngokulinganayo kwaye liya kuqulatha imathiriyeli ngokulinganayo kwi-trough kwaye iqhube embindini xa ugqitha phezu kwabangenzi nto.

Bonke abahambisi baya kuhlala befumana ukolula kobude nobubanzi babo.Ngokuqhelekileyo, kuyamkeleka ukuba ibhanti entsha iya kunweba kunye neepesenti ezi-2 ezongezelelweyo zobude bayo bokuqala.Ekubeni eli candelo liya kwongeza ubude bebhanti, ibhande lonke liya kuba ne-slack.Oku kudodobala kuya kufuneka kuthatyathwe ukuze kugcinwe uxinzelelo oluphezulu.

Okukhona ukuhambisa ixesha elide, kokukhona ukolula kuya kuba kukhulu.Ukusebenzisa i-2 yepesenti yokwelula, i-2-meter ye-conveyor ubude inokolula i-40mm, kodwa i-200-metres ye-conveyor ubude iya kuthoba i-4 yeemitha.

Ukuthatha kwakhona kunenzuzo xa ibhanti kufuneka igcinwe.Kwimeko enjalo ukuthabatha kuyayekwa kwaye abasebenzi baya kwenza isondlo ngokulula.

Iindidi zokuThatha ii-Conveyor zebhanti

Kukho ulungelelwaniso oluninzi lwe-take-ups, nganye ineenzuzo kunye neengxaki zayo.Ulungelelwaniso oluqhelekileyo lokuthatyathwa kokuhambisa ibhanti kukuthatyathwa komxhuzulane, ukuthabatha isijivu, kunye nokuthatha okuthe tye.

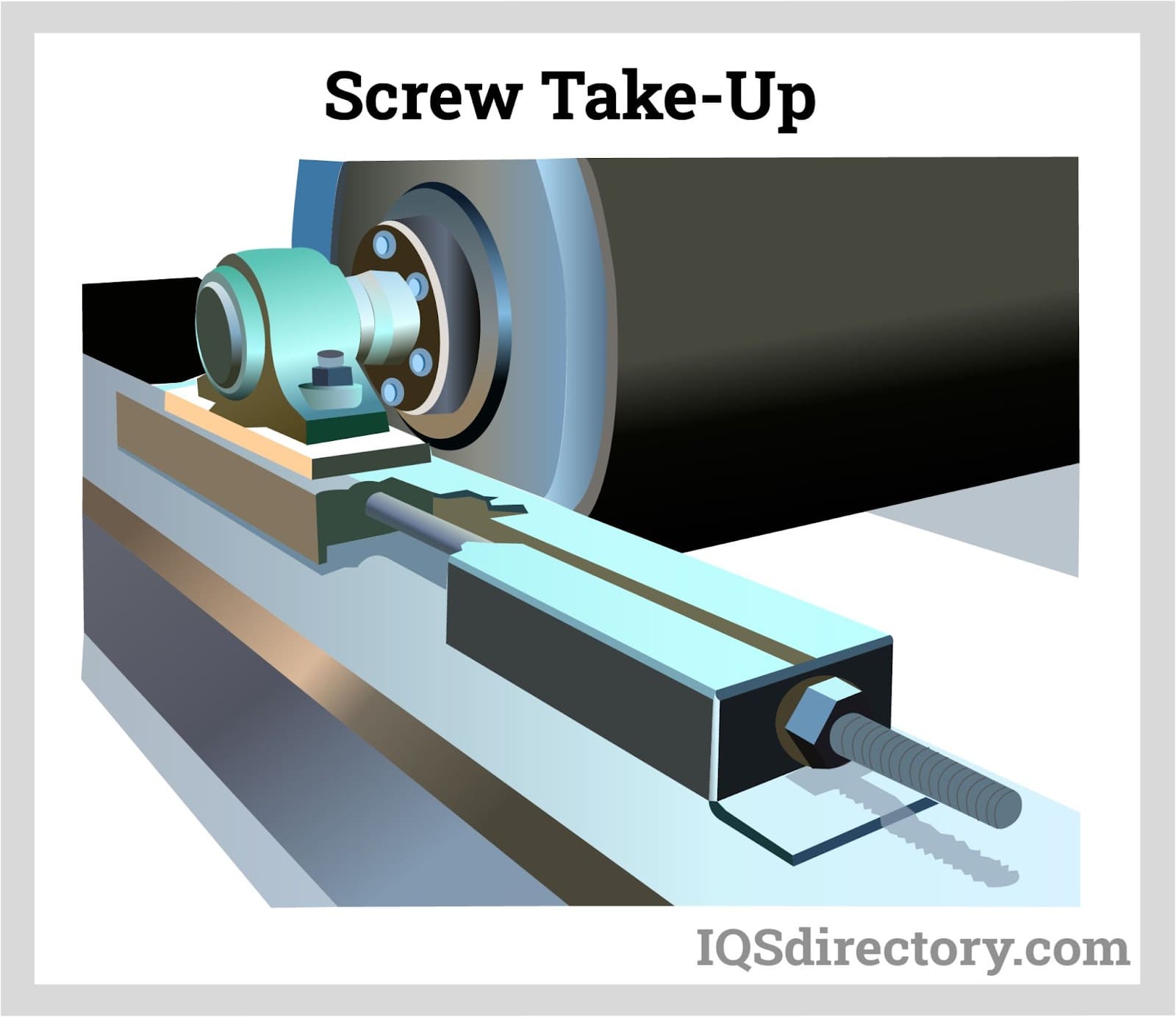

Screw Take-Up

Ubume be-screw take-up busebenzisa amandla omatshini ukuthabatha konke ukudodobala kwebhanti.Ifezekisa ngokuhlengahlengisa intonga enentambo efakwe kwenye yee-roller, ngakumbi i-roller yomsila.Le ntonga enemisonto iya kuba kwicala ngalinye le-roller ngoko inokusebenza njengenkqubo yokulungelelanisa.Kuba le yindlela yokwenza ngezandla, ukuthabatha isijivu kuhlala kubizwa ngokuba yi-manual take-up.

Esinye isimbo sibizwa ngokuba yi-top angle take-up.Nangona isaziwa, ifuna isakhelo somsila esikhulu nesinzima ukuze igcinwe.Oonogada nabo kufuneka babe bakhulu.

Ukuthabatha i-Screw-ups yindlela ephantsi nesebenzayo yokulawula ukuxinezeleka kwebhanti kubahambisi bebhanti abafutshane kwaye lolona khetho lulula noluqhelekileyo lokuthatha kwabaninzi.

Umxhuzulane Thatha-Up

Izikrufu zokuthatha i-Screw-ups ngokuqhelekileyo azifanelekanga ukufaka ubude be-stretch eyenzekayo kwii-conveyors ezinde kune-100 yeemitha.Kolu seto, ukuthatyathwa komxhuzulane kuya kuba yeyona ndlela ilungileyo yoxinzelelo lwebhanti.

Indibano yokuthatha amandla omxhuzulane isebenzisa iirola ezintathu apho ezimbini ziya kuba zii-roller ezigobileyo kwaye enye iya kuba ngumxhuzulane okanye i-sliding roller elawula rhoqo ukutsalwa kwebhanti.I-counterweight eya kunyuswa kwirola yokuthatha i-gravity itsalela ezantsi ebhantini ukugcina uxinezeleko ngomxhuzulane.Iirola ezigobileyo ziqondisa ibhanti elithambileyo lijikeleze i-roller yokuthatha umxhuzulane.

Indibano epheleleyo yokuthabatha idityaniswe phantsi kwesakhelo sokuhambisa kwaye yenza ukuxhatshazwa okuqhubekayo kwibhanti.Le ndlela yokulungelelanisa i-self-tensioning ivumela ukuthabatha ukuba kulungiswe ngokulula kwii-spikes ngokukhawuleza kuxinzelelo okanye umthwalo.

Ke, indlela yokuthatha umxhuzulane isoloko igcina ukunyanzeliswa kwebhanti efanelekileyo kwaye inqanda umonakalo kwibhanti ngenxa yomthwalo wequbuliso okanye i-tension spikes.Kuba i-gravity tensioners iyazicinezela, ifuna ukulungiswa okuncinci, ngokungafaniyo ne-screw take-up method.

Ukugcinwa kwabo ngokuqhelekileyo kuyadingeka xa ibhanti ifikelele ekupheleni kobomi bayo.Kulapho yolule kangangokuba indibano iya kuba ifikelele ezantsi kumgama obekiweyo wokuhamba.Xa oku kusenzeka, ibhanti lokuhambisa liya kufuna ukutshintshwa okanye lisikwe kwaye livulzwe.Inkqubo yokuthatha umxhuzulane yaziwa ngokuba yi-automatically take-up kuba ilungelelanisa ngokuzenzekelayo.

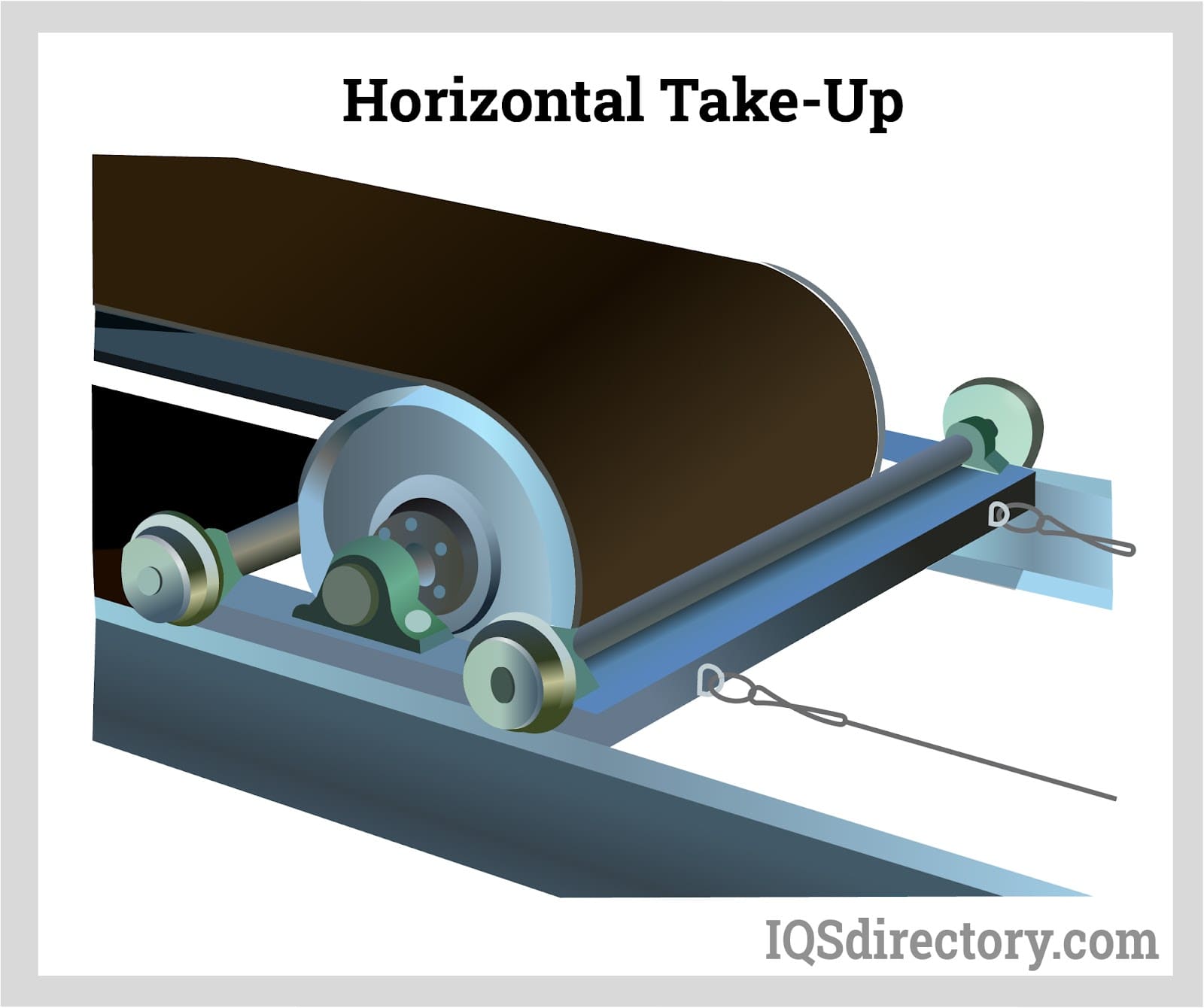

UkuThatha okuthe tye

Ukuthatha okuthe tyaba kuthathela indawo umxhuzulane kodwa kuphela xa isithuba sinqongophele.Oku kuthabatha kufana nokuthathwa komxhuzulane, kodwa endaweni yokuba indibano ibekwe ngaphantsi kwebhanti, ibekwe ngokuthe nkqo emva kwerola yomsila.Oku kwenza kube luncedo ngakumbi xa umqhubi ebekwe kwinqanaba elingenaso nasiphi na indawo eyongezelelweyo phantsi komhambisi.

Ngenxa yokuba ukuthabatha okuthe tye akuyi kuwela ngaphantsi komqhubi, ilungiselelo leentambo kunye neepuli zisetyenziselwa ukuqinisa ibhanti ngebhokisi yobunzima.Iintambo ezincanyathiselwe kwipuli yomsila zikhwela kwikhareji evumela ukuba ihanjiswe ngaphakathi nangaphandle kwendawo.

Isahluko sesi-4: Izicelo kunye neNzuzo yee-Belt Conveyors

Esi sahluko siza kuxoxa ngezicelo kunye neenzuzo zabahambisi bebhanti.Iza kuxoxa kwakhona ngeengxaki zokuhambisa ibhanti eziqhelekileyo, oonobangela bazo, kunye neziphumo zokusingqongileyo kubahambisi bebhanti.

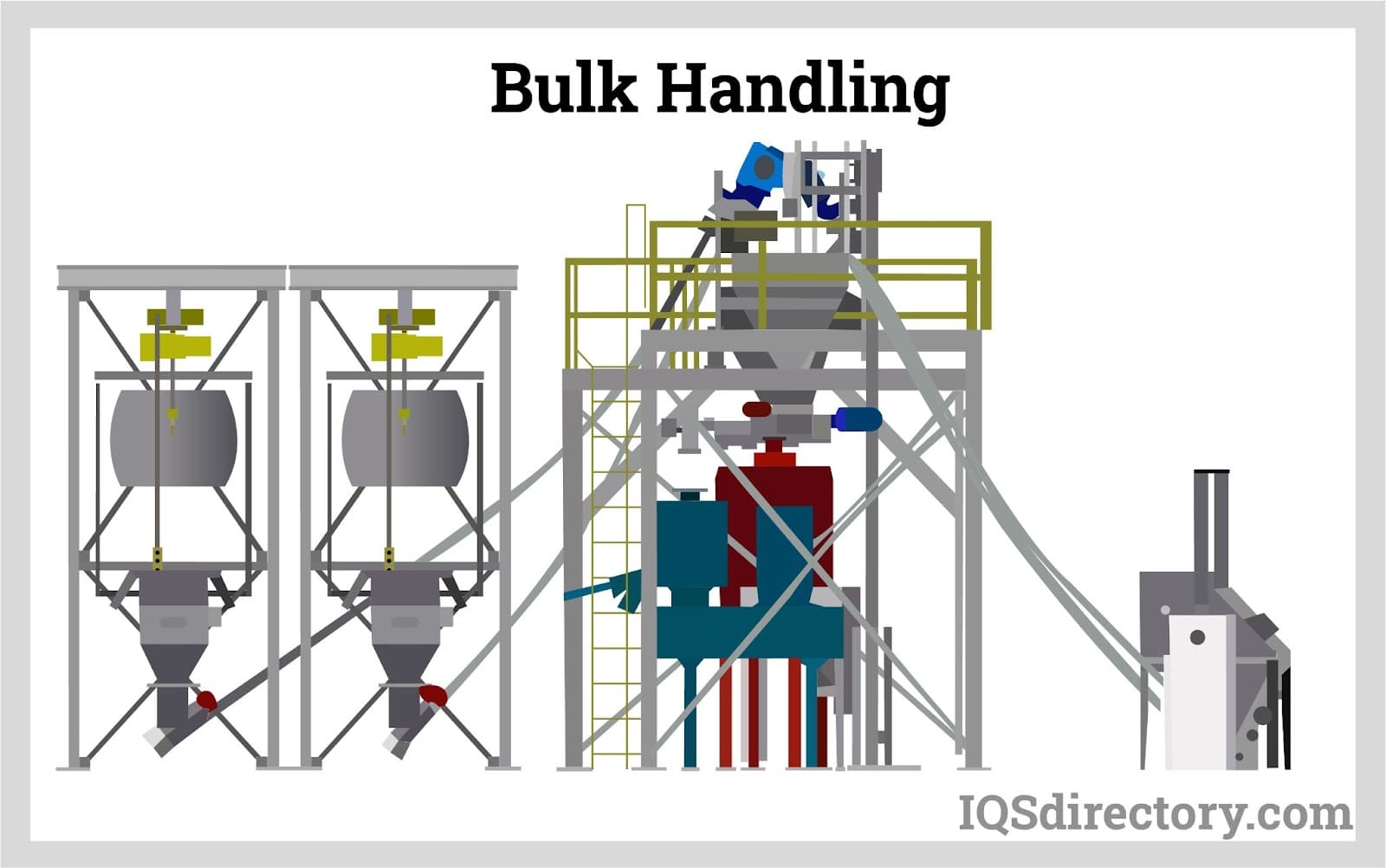

Usetyenziso lweziThuthi zeBhanti

Amabhanti okuhambisa anoluhlu olubanzi lwezicelo kuwo wonke amashishini.Ezi ziquka:

Ishishini lezemigodi

- Ukuphathwa ngobuninzi

- Ukulungiswa kwezityalo

- Ukuthatha ores ukusuka kwishaft ukuya kwinqanaba lomhlaba

Ushishino lweemoto

- Abahambisi bomgca weNdibano

- Izihambisi ezilahliweyo koomatshini be-CNC

Ishishini lezoThutho kunye neCourier

- Ukuhambisa imithwalo kwizikhululo zeenqwelomoya

- Izihambisi zokupakisha kwi-courier dispatch

Ishishini lokuThengisa

- Ukupakishwa kwendawo yokugcina impahla

- Abahambisi be-Till point

Ezinye izicelo zokuhambisa zezi:

- Amashishini okuphatha ukutya ukulungiselela ukuhlelwa kunye nokupakishwa

- Ukuveliswa kwamandla okuhambisa amalahle kwiibhoyila

- Civil kunye nolwakhiwo njengeziteshi

Izinto eziluncedo kwii-Belt Conveyors

Izibonelelo zokuhambisa ibhanti ziquka:

- Yindlela ephantsi yokuhambisa imathiriyeli kwimigama emide

- Ayithobi isidima semveliso ehanjiswayo

- Ukulayisha kungenziwa nakweyiphi na indawo ecaleni kwebhanti.

- Ngama-trippers, iibhanti zinokukhuphela kuyo nayiphi na indawo emgceni.

- Abavelisi ngxolo eninzi njengezinye iindlela zabo.

- Iimveliso zinokulinganiswa kuyo nayiphi na indawo kwi-conveyor

- Banokuba namaxesha amade okusebenza kwaye banokude basebenze iinyanga ngaphandle kokuyeka

- Ingayilwa ngendlela eshukumayo kwakunye nokuba imile.

- Yiba neengozi ezincinci kukwenzakala komntu

- Iindleko zoLondolozo oluphantsi

Iingxaki zoMhambisi weBhanti eqhelekileyo

Kukho iingxaki ezininzi apho iinkqubo zokuhambisa ibhanti zinokutyekela kuzo kwaye kuya kufuneka zithotywe.Ezi ziquka:

Ingxaki 1: I-Conveyor ibaleka ukuya kwelinye icala kwindawo ethile kwiNkqubo

Izizathu zoku ziya kubandakanya:

- Ukwakhiwa kwezinto phezu kwamavila okanye into ebangela ukuba amavila ancamathele

- Abangasebenziyo abasabaleki kwisikwere kwindlela yokuhambisa.

- Isakhelo seConveyor sithambekile, sigoso, okanye asisekho mgangatho.

- Ibhanti lalingadityaniswanga ngokulinganayo.

- Ibhanti ayilayishwanga ngokulinganayo, mhlawumbi ilayishwe ngaphandle embindini.

Ingxaki yesi-2: Ibhanti leConveyor liyatyibilika

Izizathu zoku ziya kubandakanya:

- Ukutsaleka kumbi phakathi kwebhanti kunye nepuli

- Amavila abambekile okanye akajikelezi ngokukhululekileyo

- I-pulley legging egugileyo (iqokobhe elijikeleze ipuli elinceda ukunyusa ukukhuhlana).

Ingxaki yesi-3: Ukolulwa kweBhanti

Izizathu zoku ziya kubandakanya:

- I-tensioner yebhanti iqine kakhulu

- Ukukhetha izinto zebhanti akwenziwanga kakuhle, mhlawumbi “phantsi kwebhanti”

- I-Conveyor counterweight inzima kakhulu

- Umsantsa phakathi kwe-idler rolls mde kakhulu

Ingxaki yesi-4: Ibhanti Linxiba Ngokugqithisileyo kwiMiphetho

Izizathu zoku ziya kubandakanya:

- Ibhanti ilayishwe ngaphandle embindini

- Impembelelo ephezulu yezinto eziphathekayo kwibhanti

- Ibhanti elisebenza ngokuchasene nesakhiwo sokuhambisa

- Ukuchithwa kwezinto

- Izinto eziphathekayo zibanjwe phakathi kwebhanti kunye ne-pulley

Iziphumo zokusiNgqongileyo kwiZihambisi zebhanti

Amanzi, iimveliso zepetroleum, imichiza, ubushushu, ukukhanya kwelanga, nengqele, zonke zinempembelelo kwindlela asebenza ngayo kunye nobomi bomhambisi webhanti.

Izizathu kunye neziphumo zingahlelwa ngolu hlobo:

Iziphumo zokufuma

- Ibhanti liyabola kwaye liyaqhekeka

- Ibhanti yokuncamathela ekhululekileyo

- Ibangela ukutyibilika

- Izidumbu zentsimbi zinokugqwala

Iziphumo zokukhanya kwelanga kunye noBushushu

- Irabha iya koma kwaye ibe buthathaka

- Irabha iya kuqhekeka

- Irabha inokuba nokucotha ngakumbi kwaye ngaloo ndlela inciphise ukutsalwa kwebhanti

Iziphumo ezibandayo

- Ibhanti liyaqina kwaye liba nzima ukukhokela nokuqeqesha

- Kwiinkqubo zokuthambeka, iqabaka inokwakheka kwaye ibangele ukutyibilika

- Umkhenkce unokwakheka kwiichute kwaye uzivale

Iziphumo zeOli

- Irabha iya kudumba

- Irabha iya kuphelelwa ngamandla

- Irabha iya kuphelelwa ngamandla

- Ibhanti liya kunxiba ngokukhawuleza

- Irabha iya kulahlekelwa ukunamathela

Ukuqukumbela

Ukuhanjiswa kwebhanti yinkqubo eyilelwe ukuthutha okanye ukuhambisa izinto eziphathekayo njengezinto eziphathekayo, iimpahla, kunye nabantu ukusuka kwenye indawo ukuya kwenye.Ngokungafaniyo nezinye iindlela zokuhambisa ezisebenzisa amatyathanga, ii-spirals, iihydraulics, njl.Kubalulekile ukuba uqaphele ukuqwalaselwa koyilo kunye nokusetyenziswa kweendlela ezahlukeneyo zokuhambisa ibhanti kuxhomekeke kusetyenziso olucetywayo.

Ukuphunyezwa kwevidiyo

Izibonelelo zeshishini lokuhambisa kwiinjineli

Uyilo loLwakhiwo kunye neNqanaba ye-Roller Conveyor

Ii-roller conveyorilungele ukuhambisa zonke iintlobo zeebhokisi, iibhegi, iipallets, njl.Izinto ezininzi, izinto ezincinci, okanye izinto ezingaqhelekanga kufuneka zithuthwe ngeepalethi okanye kwiibhokisi zenguqu.

Umbhobho webhanti yokuhambisa kunye neemeko zesicelo

Iumbhobho wokuhambisainoluhlu olubanzi lwezicelo.Ingaizinto zothutho ngokuthe nkqo, ngokuthe tye, kwaye ngokuthe tye kuwo onke amacala.Kwaye ukuphakama kokuphakamisa kuphezulu, ubude bokuhambisa bude, ukusetyenziswa kwamandla kuphantsi, kwaye indawo incinci.

Iintlobo zokuhambisa ibhanti ye-GCS kunye nomgaqo wokusetyenziswa

Isakhiwo esiqhelekileyo sokuhambisa ibhanti kwiifom ezahlukeneyo, umatshini wokukhwela ibhanti, umatshini webhanti we-tilt, umatshini webhanti odibeneyo, umatshini webhanti elicwebileyo, umatshini webhanti ojikayo kunye nezinye iifom.

UFUNA UKUSEBENZA NATHI?

Ixesha lokuposa: May-26-2022